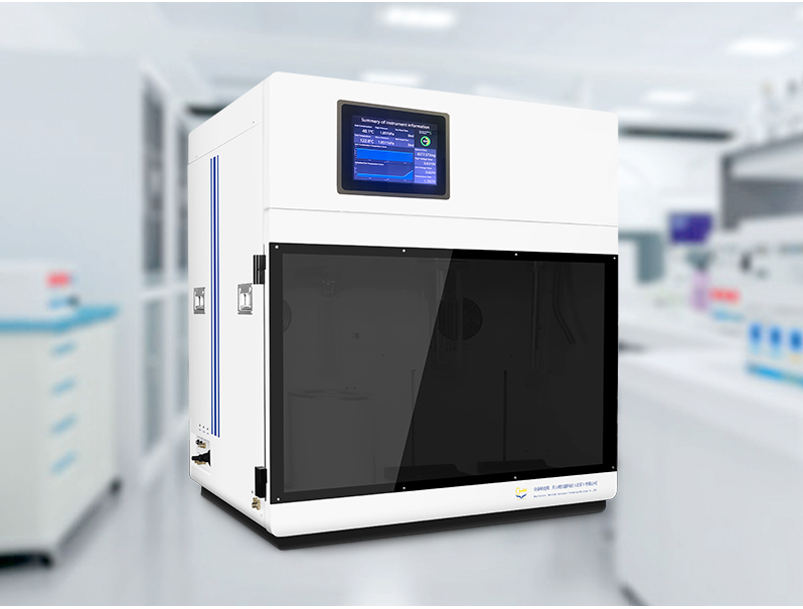

STD-VVS&DVS Series Vacuum & Dynamic Vapor/Gas Sorption Analyzer

Category:Pore Size Analyzer

Introduction

Main Function

◆ Dynamic Vapor Sorption Isotherm (DVS);

◆ Temperature-Programmed Reduction (TPR) by Dynamic Gravimetric Method;

◆ Dynamic Vapor Isobaric Adsorption/Desorption Rate (DVS);

◆ Dynamic Gas Sorption Isotherm (DGS);

◆ Evaluation of Multi-component Competitive Adsorption by Dynamic Gravimetric Method;

◆ Dynamic Gas Isobaric Adsorption/Desorption Rate (DGS);

◆ Upgradable for adsorption of corrosive vapors/gases (e.g., SO2, H2S, NH3, etc.)

◆ Temperature-Programmed Desorption (TPD) by Dynamic Gravimetric Method

Report Content

◆ Vacuum Degassing Thermogravimetric Report

◆ Adsorption/Desorption Isotherm

◆ Adsorption/Desorption Rate

Performance Parameters

Performance Parameters

| Testing Function | Details |

|---|---|

| Adsorption Performance Testing | Adsorption/desorption isotherm, adsorption kinetics, etc. |

| Isobaric Adsorption Kinetics Analysis | Isobaric adsorption/desorption rate |

| Number of Analysis Positions | Optional 4 or 8 analysis positions |

| Multi-position Simultaneous Analysis | Significantly improves testing efficiency and accelerates research progress, addressing the slow rate and low efficiency of gravimetric isobaric adsorption testing. |

| Uniform Analysis Environment | Allows for detection of subtle adsorption performance differences in materials from the same batch. |

| Resolution/Range | Imported industrial microbalance: 1ug/5000mg (0.1ug/500mg optional) Range increased by 2-5 times compared to similar products, broadening sample loading range, enhancing sampling representativeness, and improving accuracy. |

| Test Gas Types | Water vapor, organic vapor, CO2, alkanes/olefins, and other non-corrosive gases |

| Optional Corrosive Gas Adsorbates | Yes (e.g., NH3, SO2) |

| Fully Automatic Cyclic Adsorption Test (Recommended) | Fully automatic constant pressure and variable temperature adsorption/desorption Fully automatic constant temperature and variable pressure adsorption/desorption Fully automatic variable temperature and variable pressure adsorption/desorption Fully automatic cyclic adsorption/desorption lifetime evaluation |

| Degassing Furnace and Constant Temperature Bath Switching Mode (Recommended) | Fully automatic switching Specifically for fully automatic cyclic adsorption lifetime evaluation |

| Adsorption Test Temperature | Constant temperature bath: -5℃~150℃, precision ±0.1℃ |

| Vapor Anti-condensation | Full constant temperature gas path system: room temperature~60℃, precision 0.1℃ |

| Vapor Generation Method | “Carrier gas mixing” flow method |

| Vapor “Humidity/Partial Pressure” Control Range | 2%~98% P/P0, lower P/P0 optional |

| Reagent Tube Liquid Reagent Capacity | 120ml Patented technology for saturated condensate recovery of reagents, improving reagent utilization and reducing consumption. |

| Degassing Activation Pretreatment | Atmospheric purge degassing Room temperature~300℃, precision ±0.1℃ |

| Visual Programmed Temperature Degassing | Degassing temperature control mode: multi-stage programmed temperature rise to prevent overheating, protect samples, and prevent sample flying. Real-time visualization of sample constant weight process to accurately determine if degassing is complete. |

| Buoyancy Correction | Mode 1: Buoyancy calculation mode (default) Mode 2: Blank position buoyancy background subtraction mode Mode 3: Background subtraction curve mode |

| Blank Position Synchronous Testing | Supports blank position as background and buoyancy subtraction synchronous testing Eliminates system errors and significantly improves testing accuracy and stability |

| Mass Flow Controller | Imported high-precision mass flow controller (MFC) Enables precise control of gas and vapor concentrations |

Key IndicatorsVacuum MethodDynamic MethodMethod OverviewAdsorbent sample is placed in a vacuum environment. Adsorbate vapor volatilizes into the vacuum system under controlled partial pressure (P/P₀). Time-weight data is continuously recorded until adsorption equilibrium is reached.

Also called “static method” as adsorbate vapor is static during adsorption.

Ideal for physical adsorption analysis with high data reliability. No carrier gas interference. Technically advanced method developed later than dynamic method.Adsorbent sample is placed in a normobaric environment with flowing carrier gas. A mixture of carrier gas and adsorbate vapor flows over the sample. Time-weight data is continuously recorded until adsorption equilibrium.

Also called “dynamic method” due to flowing adsorbate vapor.

Early method developed from simple “balance +Constant temperature and humidity chamber” setups. Requires no vacuum system, simpler construction, widely adopted historically.Sample PretreatmentVacuum Degassing (High Efficiency)Atmospheric Purging (Low Efficiency)

– Removes surface impurities (e.g., moisture, air) via heating + vacuum pumping.- Removes impurities via heating + dry carrier gas purging.

– Effective for high-surface-area samples (microporous materials, molecular sieves, activated carbon).- Limited effectiveness for removing impurities in micropores.

– Pretreatment temperature up to 400℃, no secondary contamination.- Maximum pretreatment temperature ≈200℃.

– Clean sample surface ensures accurate test data.- Risk of sample loss during vacuum oven drying (no anti-blowout mechanism).

– Sample re-exposure to air during transfer compromises pretreatment effectiveness.Vapor Introduction Method– After vacuum degassing, sample chamber is evacuated. Adsorbate vaporizes from liquid reagent into the chamber and adsorbs onto the sample.- Sample is under normobaric conditions. Carrier gas carries adsorbate vapor dynamically over the sample.

– P/P₀ control via precise vapor pressure regulation.- P/P₀ control via carrier gas/vapor ratio adjustment.Partial Pressure Control– Precision: Error <0.1%- Precision: Error ≈1%

– Range: 0–99%- Range: 2–90%

Disclaimer: The above content is for reference and communication only among industry insiders, and does not guarantee its accuracy or completeness. According to relevant laws and regulations and the regulations of this website, units or individuals who purchase related items should obtain valid qualifications and qualification conditions.