UV Protection for Textiles

Blog 19 9 月, 2025

Although summer is almost over, have you ever wondered, while basking in the scorching sun, how can a thin layer of fabric truly block UV rays? Is UPF 50+ just a waste of money? What’s the secret behind UV protection in textiles? How do manufacturers produce these figures when manufacturing clothing? How do they conduct their testing? Let me reveal the secrets!

Ultraviolet Rays: The Invisible Skin Killer

1. Classification and Penetration of Ultraviolet Rays

•UV-A (315-400nm): Has the strongest penetrating power, reaching directly into the dermis and causing photoaging (wrinkles, sagging, and dark spots).

•UV-B (280-315nm): Has the highest energy, causing sunburn and erythema. Long-term exposure increases the risk of skin cancer.

•UV-C (100-280nm): Blocked by the ozone layer, but caution is advised in areas with ozone depletion.

2. The Necessity of UV Protection for Textiles

• Ordinary clothing only blocks 50%-70% of UV rays, and thin cotton and linen fabrics offer even less protection.

• Long-term UV exposure not only harms the skin but can also cause fabric fading and brittleness (e.g., car interiors and outdoor tents).

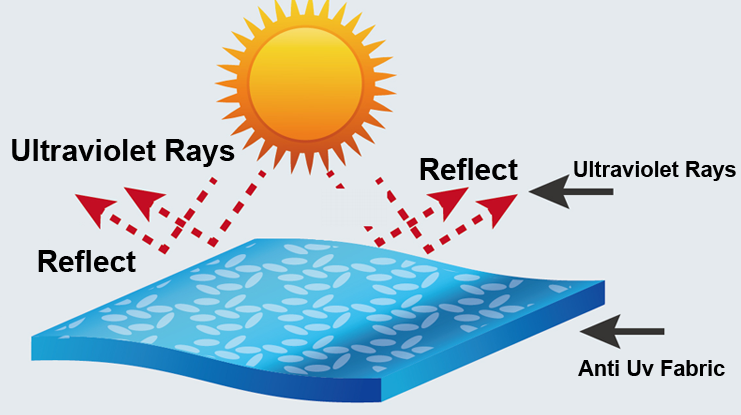

UV Protection for Textiles: Three Core Principles

1. Reflection/Scattering: “Blocking Light with a Shield”

• Materials: Inorganic particles such as nano-titanium dioxide (TiO₂) and zinc oxide (ZnO).

• Principle: Refraction at the interface between particles and fibers reflects or scatters UV rays (similar to a mirror effect).

• Advantages: Highly washable, suitable for outdoor equipment (e.g., sun protection clothing and parasols).

2. Absorption/Conversion: “Converting Light into Heat”

• Materials: Organic compounds such as benzotriazoles and benzophenones

• Principle: Molecules absorb UV energy and release it as harmless heat.

• Advantages: Lightweight, breathable, suitable for undergarments and car interiors.

3. Physical Shielding: “Densely Woven Netting”

• Method: High-density fibers (such as polyester and nylon) + tightly woven structure.

• Principle: Reduce fabric porosity to block UV penetration.

• Data: UPF values increase exponentially with thickness and density.

Key Indicators and Testing Standards for UV-Proof Textiles

1. Core Indicators

• UPF (Ultraviolet Protection Factor): UPF 40+ is considered acceptable (blocks 97.5% of UV rays); UPF 50+ is considered high-quality (blocks over 98%).

• UVA Transmittance: Must be <5%, for more effective protection against long-wave UV rays.

2. Domestic and International Testing Standards

| Standard | Core Requirements | Scope of Application | Characteristics |

|---|---|---|---|

| AS/NZS 4399 | UPF ≥ 15, three levels of protection (UPF 15-50+) | Dry, non-stretch fabrics | The first UV protection standard; labels must indicate UPF value and protection level. |

| EN 13758 | UPF>40,UVA transmittance < 5% | Apparel fabrics (excluding products like umbrellas) | Strictly distinguishes between homogeneous and non-homogeneous fabrics; stretching or wetness reduces protection. |

| AATCC 183 | UPF≥15,four levels of protection (UPF 15-40+) | Dry/wet/stretched fabrics | Pre-treatment simulates two years of use (40 washes + 100 AFU light exposure); test results are closer to real-life performance. |

| GB/T 18830 | UPF>40,UVA transmittance < 5% | All textiles | Similar to the EU standard, but with lower requirements; must indicate that wetness and stretching reduce protection. |

| UV-Standard 801 | No mandatory minimum UPF; performance tested after pre-treatment (friction, washing, stretching) | Apparel, sun-protective textiles (umbrellas, curtains, etc.) | Simulates real-life use; label UPF values range from 2 to 80; suitable for high-risk areas. |

Manufacturing Process for UV-Proof Textiles

1. Fiber Modification Technology

• Co-spinning: Nano-TiO₂ and ZnO masterbatch are blended with polyester chips to create UV-resistant fibers.

• Resin Finishing: Coating the fiber surface with a UV-absorbing resin (suitable for industrial use).

2. Finishing Processes

• Padding: Fabric is soaked in a UV-blocking slurry and then cured at high temperature (low cost, suitable for large quantities).

• Coating: Surface sunscreen coating is sprayed on.

• Magnetron Sputtering: Vacuum-coated nano-metal films (such as silver and gold plating, providing both sun protection and heat insulation, a luxury-grade finish).

3. Industry Innovation

• Intelligent Temperature-Regulating Fabrics: Combining phase change materials to provide sun protection while regulating perceived temperature。

Fabric UV Tester

The Fabric UV Tester is a high-precision instrument designed specifically for evaluating the optical properties of sunscreen products and cosmetics. It utilizes a light source system that closely resembles the characteristics of the solar spectrum, a highly stable UV-Vis spectrophotometer, and comprehensive control and data analysis software to automatically measure the SPF value and other key indicators of sunscreen products. This instrument effectively replaces traditional human (in-vivo) testing methods, significantly reducing testing costs and significantly improving testing efficiency and convenience.

The instrument complies with multiple major international standards, including AATCC 183. AS/NZS 4399. ISO 24443. Colipa 2011. and FDA, ensuring wide applicability and authoritative certification.

Broad spectral coverage and excellent optical performance:

The instrument covers the UVA and UVB regions, with a spectral range of 290–400 nm, a wavelength repeatability of 0.25 nm, and the system supports selectable 1 nm or 2.5 nm data recording and storage intervals. Monochromatic resolution reaches up to 1.66 nm, and wavelength accuracy error does not exceed ±0.2%, ensuring highly repeatable and accurate data acquisition.

Intelligent data analysis and management software:

It includes a powerful built-in control and computational analysis system, supports dual output modes for data and graphics, and integrates the Boots star rating model. The instrument can simultaneously test up to 36 samples, automatically displaying MPF and absorbance values. It also features photostability analysis, automatically calculating UVA/UVB ratios, UPF values, critical wavelengths, and in vitro UVA test results. It also supports networking and online help.

Stable and Reliable Light Source and Detection System:

A 125W xenon arc lamp provides stable UV and near-UV radiation output. Combined with a high-performance integrating sphere, this ensures excellent reproducibility and accuracy during testing.

Excellent Traceability and Linearity:

Backed by one year of NIST traceability data, the instrument boasts a linearity rating of up to 99.997%, ensuring data reliability and comparability over long-term use.

Automated Sampling and Multifunctional Testing Modes:

The software-controlled sample platform supports automated scanning and timed measurement. Up to 12 sampling points can be set for automated continuous testing, automatically stopping and saving data upon completion. This meets both standard testing requirements and supports long-term light resistance testing.

Comprehensive Calibration and Maintenance Mechanism:

The instrument comes with a NIST-verified calibration kit, allowing users to perform independent calibration and routine maintenance, ensuring it always operates in optimal condition.

Buying Guide: 4 Steps to Avoid Sunscreen Traps

1.Check the Label: Look for UPF 40+/50+ and the testing standard (e.g., GB/T 18830).

2. Material Selection:

• Recommended: Polyester and nylon (excellent sun protection) > wool and silk > cotton and linen.

• Beware: Light fabrics such as bleached cotton and lace (UPF may be <10).

3. Check the Craftsmanship:

• Prioritize: Built-in sun protection in the fiber > surface coating.

4. Inspect Details:

• Dark colors > light colors (black absorbs UV rays more effectively).

• Designs such as seam covers and a wider brim enhance protection.

Industry Trends

1. Multifunctionality: Three-in-one fabrics offering sun protection, antibacterial protection, and stain resistance.

2. Visual protection: UV-sensitive color-changing fibers provide real-time display of protection effectiveness.

3. Environmental innovation: Recyclable sun protection fibers reduce microplastic pollution.

The fabric UV tester is not only suitable for evaluating the UV protection performance of sunscreen cosmetics, textiles, and related materials, but is also an indispensable tool in quality control, R&D testing, and regulatory compliance. Its scientific design, efficient operation, and excellent standard compliance make it the preferred instrument for UV optical testing in modern industrial and laboratory environments.