Material Smoke Toxicity Test Insights

New 29 10 月, 2025

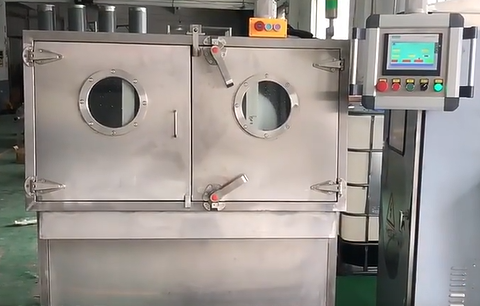

The Material Smoke Toxicity Test Device is a core instrument in the field of fire safety science. By simulating the thermal decomposition and combustion processes of materials in a real fire, it quantitatively analyzes the composition and concentration of toxic components in the smoke, providing a scientific basis for material safety evaluation and classification. This type of equipment has become a key tool for verifying compliance with fire safety standards in modern building materials, rail transportation, aerospace, and other fields.

I. Technical Principle and Workflow

The core of the Material Smoke Toxicity Test Device is to simulate the behavior of materials in a fire through controlled thermal decomposition and collect smoke for toxicological evaluation:

Annular Furnace Heating System

The electrically heated circular furnace covers a temperature range of 300°C to 1200°C, with a static temperature control accuracy of ±0.5°C and a dynamic temperature fluctuation of no more than ±2.5°C. The furnace moves axially along the quartz tube at a rate of 10 mm/min, simulating the entire process from smoldering to open flame. The quartz tube has an inner diameter of 47 mm and a length ≥600 mm. A quartz boat containing the sample (standard mass 10 ± 0.1 g) is placed inside to ensure uniform heat distribution.

Smoke Generation and Distribution

Carrier gas (air) is introduced into the system at a flow rate of 0-20 L/min, precisely controlled by a rotameter. The generated smoke is switched through a three-way stopcock and thoroughly mixed with the diluent gas in a mixing chamber before being delivered to the exposure chamber. The smoke duct has a nominal diameter of 36 ± 1 mm to reduce flow resistance.

Animal Exposure and Observation

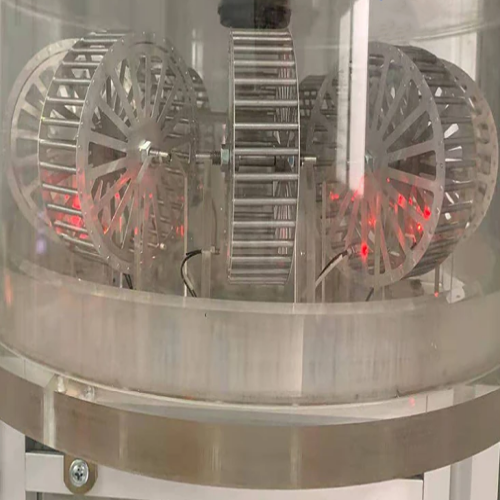

The exposure chamber is made of transparent plexiglass, has a volume of approximately 10 L, and can accommodate 10 mice for simultaneous exposure. Mice are placed in aluminum cages (mass 60 ± 10 g) that can rotate freely to monitor their movement. A video monitoring system records mouse behavior in real time, and quantifies poisoning symptoms based on the cage rotation frequency.

Table: Key Parameters of the Material Smoke Toxicity Test Apparatus

| Modules | Parameters | Typical Values |

| Heating system | Temperature Range/Accuracy | 300-1200°C / ±0.5°C (static) |

| Motion system | Displacement Rate/Distance | 10±0.01 mm/min / ≥600 mm |

| Gas supply | Air Flow Adjustment Range | 0-20 L/min |

| Contamination chamber | Effective Volume/Mouse Capacity | 10 L / 10 units |

| Overall equipment | Dimensions/Weight | 1800 × 600 × 1750 mm / 460 kg |

II. Core Components and Technological Innovations

Modern test equipment improves data reliability through mechatronics and intelligent monitoring:

Precision Temperature Control System: A PLC controller employs a PID algorithm (proportional-differential-integral control) with real-time feedback from K-type thermocouples to ensure stable furnace temperature during dynamic scanning.

Dynamic Heating Mechanism: A servo-motor-driven linear module achieves reciprocating motion in the circular furnace, preventing localized overheating and simulating the uneven heating of materials in a real fire.

Multi-Mode Smoke Gas Collection System: This system supports FTIR spectroscopy (e.g., ISO 19701) in conjunction with electrochemical sensors, enabling simultaneous detection of 8-10 gases, including CO, HCN, HCl, and HF, with detection limits as low as ppm.

Animal Exposure Monitoring System: An integrated high-precision tachometer records the number of cage rotations, quantifies the decline in mouse activity, and integrates video analysis software to automatically identify behaviors such as convulsions and coma.

III. Standard System and Grading Method

While mainstream global standards differ in testing details, they all use the toxicity equivalent model as the core evaluation basis:

Comparison of International Mainstream Standards

China GB/T 20285-2006: Using the mouse cage method, toxicants are classified into three levels: S1 (low toxicity), S2 (moderate toxicity), and S3 (high toxicity) based on the mortality rate of mice after 30 minutes of exposure.

US ASTM E1678: Limits the radiant heat flux to 50 kW/m² and calculates the lethal toxicity equivalent (TEQ) using the N-gas model:

TEQ = [CO] + 5.5 [HCN] + 2.1 [HCl] + 3.6 [HF].

EU DIN 53436: Emphasizes the impact of ventilation conditions on thermal decomposition products and requires that the carrier gas flow rate be strictly matched to the material quality.

Aviation-Specific HB 7066: For aircraft cabin materials, smoke is collected at 4 and 8 minutes to test for six gases, including CO, NOₓ, and HCN.

Toxicity Classification Criteria

S1: TEQ ≤ 1.0% (based on CO)

S2: TEQ 1.0%-2.5% with no single component exceeding the specified limit

S3: TEQ > 2.5% or any component exceeding the specified limit (e.g., HCl > 150 ppm).

Table: Safety Thresholds for Major Toxic Gases

| Gas | Primary Source Materials | IDLH value | Lethal Concentration |

| CO | All carbon-containing materials | 1200 ppm | 0.5% (volume fraction) |

| HCN | Polyurethane, nylon | 50 ppm | ≥150 ppm (10 minutes) |

| HCl | PVC, flame retardants | 50 ppm | >1000 ppm |

| HF | Fluoropolymers (e.g., PTFE) | 30 ppm | – |

| NO₂ | Nitrogen oxidation at high temperatures | 20 ppm | – |

The development of material smoke toxicity testing equipment has progressed from the mouse cage method, which relied on animal behavioral observation, to a new stage where high-precision gas analysis and computational toxicology models are combined. Future work is needed to further bridge the gap between laboratory classification and real-world fire toxicity, providing closed-loop verification tools for the development of “low-smoke toxicity” flame-retardant materials. After all, in a smoke-filled fire, every reduction in toxicity can potentially save lives.