The working principle of the cone calorimeter

New 10 11 月, 2025

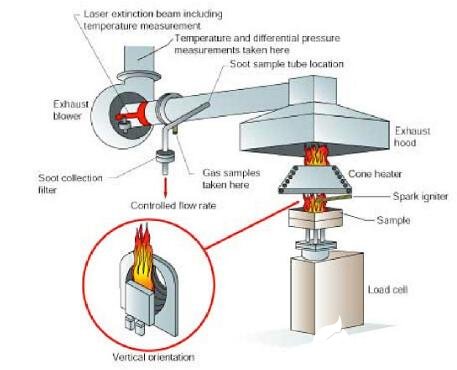

A cone calorimeter measures the heat release rate of materials based on the oxygen consumption principle. This principle states that the amount of heat released per unit of oxygen consumed during material combustion is essentially constant. When a specimen is exposed to the heat source from a conical heater, the cone calorimeter measures the specimen’s heat release rate, smoke production rate, time to ignition, oxygen consumption, carbon monoxide and carbon dioxide production, and mass loss rate. The heat generated is directly proportional to the fire severity, such as the fire growth rate. To determine material flammability, it is exposed to an external radiant heat source.

A sample is placed under a conical radiant heater. Typically, the sample is exposed to an external heat flux of 35 kW/m² from the heater. However, for more fire-resistant materials, the heat flux is often increased to 50 kW/m². Once sufficient pyrolyzates are generated, ignition occurs. The combustion products pass through the cone heater and an instrumental exhaust duct. Measured or calculated values of primary importance include, but are not limited to, time to ignition, mass loss rate during combustion, peak values and their times during burning, and the total heat released during the test.

The cone calorimeter complies with the following test standards:

ISO 5660: Reaction to fire tests – Heat release, smoke production and mass loss rate

ASTM E 1354: Standard Test Method for Heat and Visible Smoke Release Rates for Materials and Products

BS 476 Pt.15: Fire tests on building materials and structures – Method for measuring the rate of heat release of products

GB/T 16172-2007: Test method for heat release rate of building materials