Tracking Test Apparatus: Applications & Standards

Blog 3 12 月, 2025

The Tracking Test Apparatus, also known as a Leakage Trace Tester, is a precision instrument designed for leak detection in sealed systems. Combining non-destructive testing methods with high sensitivity, it enables engineers to quickly locate fluid or gas leaks using fluorescent dye tracing or smoke visualization. This device is widely used in industries such as automotive, aerospace, industrial equipment, and medical devices.

Product Overview

This handheld, portable Leakage Trace Tester detects micro-leaks as small as 0.1 μm. Equipped with dual detection modes—fluorescent dye and smoke tracing—it provides versatile inspection capabilities under various conditions. Key features include:

Rechargeable Li-ion battery with 8 hours of continuous operation

Ergonomic design with rotatable 360° detection head

IP54-rated housing for dust and water resistance

LED and audio indicators for leak severity assessment

Compliance Standards

ISO 10110-3: Optical fluid leakage testing

ASTM E1137: Dye penetrant standard

CE EN 61010-1: Electrical safety

Technical Specifications

| Parameter | Specification |

|---|---|

| Detection Accuracy | ±0.5 mm leak path resolution |

| Detection Sensitivity | 0.1 μm micro-leaks |

| Working Temperature | -20°C to 150°C |

| Illumination Range | UV-A 365 nm, 1000 μW/cm² |

| Smoke Generation | Non-toxic mineral oil-based vapor |

| Dimensions | 280 × 120 × 65 mm (L×W×H) |

| Power Supply | Rechargeable Li-ion battery, 8h continuous use |

| Device Type | Portable handheld |

| IP Rating | IP54 dust/water resistance |

Applications

Automotive: Fuel injector testing, brake system diagnostics

Industrial: Pipeline joint inspection, HVAC system leak mapping

Aerospace: Hydraulic fitting validation under pressure

Medical: Sterile seal integrity verification

Advantages

High Sensitivity: Detects leaks down to 0.1 μm.

Dual Detection Modes: Dye and smoke options for comprehensive analysis.

Portable: Lightweight and handheld, ideal for field inspections.

Ergonomic Design: Rotatable head and anti-slip grip for easy operation.

Safety Compliance: Meets IP54, ASTM, ISO, and CE standards.

Disadvantages

Battery life may limit long-term operations without recharging.

Smoke mode is less effective in windy or open-air environments.

Fluorescent dyes must be handled carefully to prevent contamination.

Product Types

Handheld Portable Leak Detector – battery-powered, compact for field use.

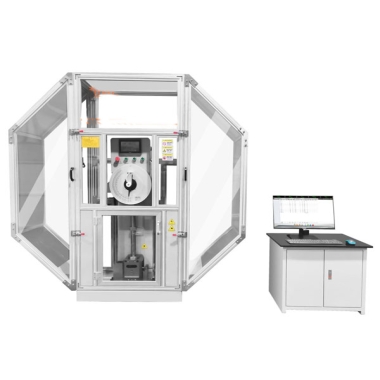

Tabletop/Bench-Mount Model – larger, laboratory-focused for detailed analysis.

Integrated Industrial System – networked solution for continuous monitoring of pipelines or HVAC systems.

Usage Precautions

Wear PPE when handling fluorescent dyes.

Avoid direct eye exposure to UV light.

Maintain at least 1 meter from open flames.

Keep the detection head clean for accurate readings.

Store in a dry, temperature-controlled environment when not in use.

FAQ

Q: What is the minimum leak size it can detect?

A: Micro-leaks as small as 0.1 μm.

Q: Can it be used outdoors?

A: Yes, but avoid extreme wind or rain conditions.

Q: How long does the battery last?

A: Up to 8 hours of continuous operation.

Q: Can both dye and smoke modes be used on the same sample?

A: Yes, sequential use provides comprehensive detection.

Q: How is leak severity indicated?

A: Through LED indicators (green/yellow/red) and an adjustable audio alarm.

As a professional laboratory instrument manufacturer, we specialize in high-quality Tracking Test Apparatus and other testing solutions. For detailed specifications, quotations, or customized solutions, please contact us directly. Our team provides expert guidance and support for all your leak detection needs.