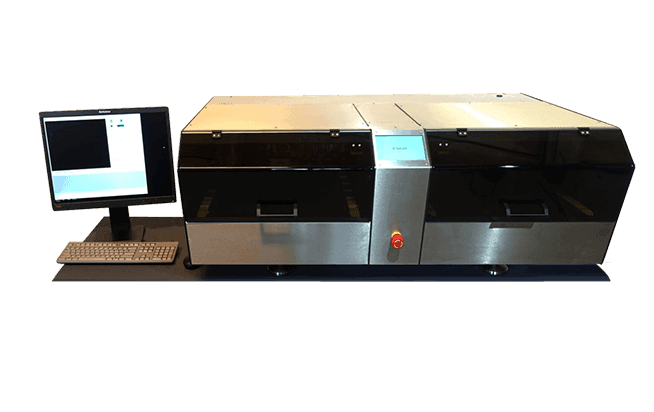

Steel wheel wear testing machine

Category:Other

Introduction

Product Introduction

The Steel Wheel Wear Testing Machine is designed for evaluating the deep abrasion resistance of unglazed tiles, cement bricks, and other inorganic floor materials. The system adopts a cycloidal pinwheel reducer, offering a large reduction ratio, compact structure, smooth transmission, and adjustable abrasive flow. This helps minimize abrasive consumption while ensuring stable and accurate test conditions.

The machine uses a gear-driven deceleration system to maintain a steel wheel rotation speed of 75 r/min. Compared with belt-driven systems, the gear mechanism ensures smooth operation without slippage. The steel wheel operates under time relay control, allowing automatic shutdown once the preset test duration is reached.

With its reasonable structure, easy operation, stable performance, and attractive design, the testing machine is highly suitable for laboratory wear resistance evaluation of cement bricks and related building materials.

Meeting Standards

GB/T 3810.7-2016 — Test Method for Abrasion Resistance of Unglazed Tiles

ISO 10545-6 — Ceramic Tiles: Determination of Deep Abrasion Resistance

GB/T 12988-2009 — Test Method for Abrasion Resistance of Inorganic Floor Materials

EN 932-5 — Tests for General Properties of Aggregates

ISO 565 — Test Sieves, Metal Wire Cloth

ISO 3310-1 — Test Sieves: Wire Cloth Test Sieves

ISO 3310-2 — Test Sieves: Perforated Metal Plate

ASTM E11 — Specification for Woven Wire Test Sieve Cloth and Test Sieves

ASTM C323 — Abrasion Resistance of Ceramic Tile

BS 410-1 — Test Sieves: Technical Requirements for Test Sieves

BS 410-2 — Test Sieves: Technical Requirements for Test Sieves Made from Perforated Metal

Product Advantages

Provides accurate, stable, and repeatable wear resistance testing for various building and ceramic materials.

Fully compliant with major national and international test standards such as GB/T 3810.7, ISO 10545-6, and GB/T 12988.

Cycloidal pinwheel reducer ensures smooth transmission, high reduction ratio, and adjustable abrasive flow, reducing abrasive usage.

Gear drive deceleration system prevents slippage and guarantees consistent wheel rotation speed.

Automatic time relay control enables programmed test duration and automatic machine shutdown.

Simple design, easy operation, and durable structure suitable for long-term laboratory testing.

Capable of simulating long-term abrasive wear in controlled test conditions.

Product Features

Cycloidal pinwheel reducer for stable and efficient deceleration.

Gear-driven system that ensures precise, slip-free steel wheel rotation.

Two steel grinding wheels available (thickness 10 mm and 70 mm) with high hardness for long service life.

Time relay for controlling steel wheel rotation time and automatic shutoff.

Abrasive feeding system with adjustable flow rate and hopper volume above 5L.

Sample holder designed for 100 × 110 mm specimens.

Two different weight sets supplied to meet multiple testing standards.

Digital time display for real-time monitoring of test duration.

Technical Parameters

| Item | Specification |

|---|---|

| Grinding Wheel 1 | Ø200 ± 0.2 mm × 10 ± 0.1 mm |

| Grinding Wheel 2 | Ø200 ± 0.2 mm × 70 ± 0.1 mm, Hardness HB203–245 |

| Grinding Wheel Speed | 75 ± 4 r/min (constant) |

| Sample Size | 100 mm × 110 mm |

| Abrasive | ISO 8486-1986 F80 White Fused Alumina |

| Abrasive Feed Rate | (100 ± 10) g per 100 r, adjustable |

| Hopper Volume | > 5 L |

| Test Time | Preset, digital display |

| Weight 1 | 2.5 kg (GB/T 3810.7-2006) |

| Weight 2 | 14 kg (GB/T 12988-1991) |

| Overall Dimensions | 600 × 580 × 1300 mm |

| Machine Weight | About 150 kg |

FAQ

1. What materials can be tested with this machine?

The machine is mainly used for unglazed ceramic tiles, cement bricks, paving blocks, and other inorganic flooring materials that require abrasion resistance evaluation.

2. Why does the machine use a cycloidal pinwheel reducer?

The reducer ensures high torque output, smooth transmission, and stable wheel speed. It also reduces abrasive consumption by enabling adjustable flow control.

3. How is the abrasive supplied during testing?

A hopper (≥5 L) feeds F80 white alumina abrasive at a controlled and adjustable flow rate, ensuring consistent wear conditions throughout the test.

4. What is the purpose of the two different steel grinding wheels?

Different wheel thicknesses meet the requirements of different test standards and allow simulation of varying abrasion conditions.

5. Does the machine stop automatically after a test?

Yes. The time relay controls the operation duration and automatically shuts down the machine once the preset time is reached, improving convenience and safety.