Automatic Wire Stripping Machines

Category:Other

Introduction

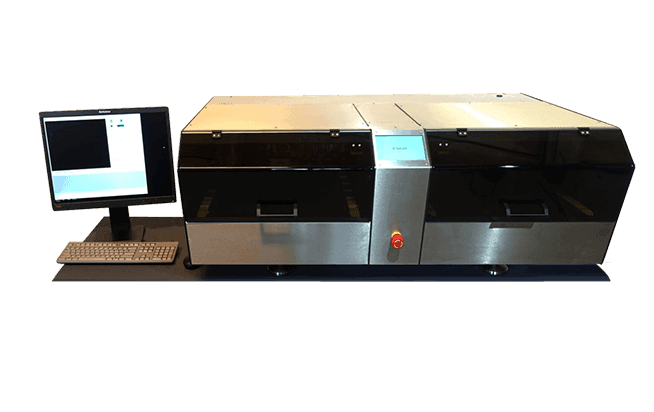

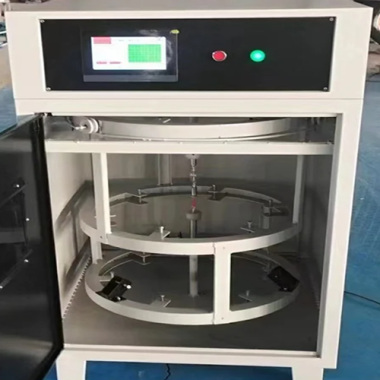

Product Overview

The Automatic Wire Stripping Machine is a precision instrument designed to evaluate the insulation strength of automobile wires and to automate the stripping process. It is an essential testing tool for wire manufacturers, automotive cable producers, and quality control laboratories, ensuring consistent performance and safety of automotive electrical systems.

By combining controlled cutting force, acceleration, and automated data recording, the machine provides reliable, repeatable, and accurate results for wire insulation and stripping performance.

Applicable Standards

SAE J1128-2005 – Standard for automotive low-voltage primary cables

Compliance with this standard ensures that the testing and stripping results meet international automotive industry requirements.

Technical Parameters

| Parameter | Specification |

|---|---|

| Application force range | 12–20 kg, 1–200 kg |

| Acceleration speed adjustment | Potentiometer adjustment or computer software automatic control |

| Acceleration speed | 2.3 kg/min |

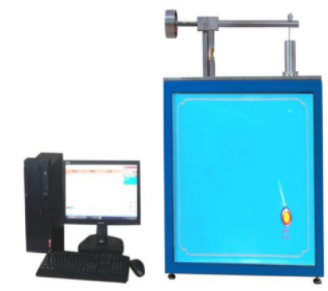

| Steel rod diameter | 3 mm |

| Test voltage | 24 V |

| Detection action current | 5 mA |

| Motor type | Ordinary speed motor or servo motor |

| Power | 500 W |

| Power supply | AC 220 V |

| Data reporting | Generates test report files |

Scope of Application

Automotive industry: Testing and stripping automotive wires and cables.

Cable manufacturers: Ensuring insulation strength and consistency of wire batches.

Quality control laboratories: Automated, precise, and repeatable evaluation of wire insulation durability.

R&D departments: Developing new wire types and optimizing insulation materials.

FAQ

1. What type of wires can be tested with this machine?

The machine supports automotive low-voltage wires in compliance with SAE J1128, including standard copper and copper alloy conductors with PVC, PE, or XLPE insulation.

2. How is the wire stripping process controlled?

Stripping is performed using adjustable application force and precisely controlled acceleration speed, either manually via a potentiometer or automatically via software. This ensures repeatable results without damaging the conductor.

3. Can the machine generate reports automatically?

Yes, the system records the applied force, stripping cycles, and test conditions, and generates a test report file for quality control and documentation purposes.

4. How is the machine powered and operated?

The machine operates on AC 220 V and is equipped with either a standard speed motor or a servo motor, depending on the precision requirements. Safety measures are incorporated to prevent overload or damage during testing.

5. What is the purpose of the detection action current?

The 5 mA detection current ensures that the machine can detect insulation breakthrough during testing, stopping automatically to prevent damage to the conductor and record the failure point.