Anti-drilling and Lint Tester (Impact Method)

Category:Fabric & Textile Tester

Introduction

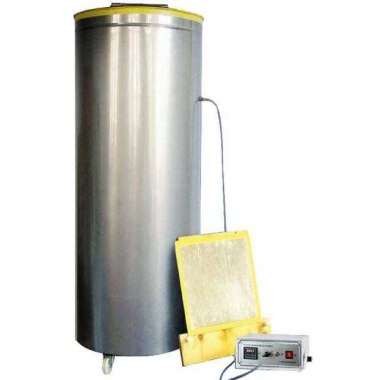

The Anti-drilling and Lint Tester (Impact Method) is a specialized testing device designed to evaluate the anti-drilling performance of fabrics, particularly those used in down products such as down quilts and down jackets. This innovative tester uses an impact method to simulate real-world stress on fabric samples, ensuring that the materials meet high standards of durability and quality.

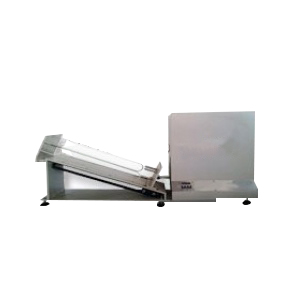

The testing process involves preparing the fabric sample into a cylindrical bag filled with feathers, down, or a mixture of both. This sample bag is then placed on an inclined plane where it undergoes repeated impacts from a needle fixed on a movable plate. The needle compresses and strikes the sample bag multiple times, simulating the wear and tear that the fabric might experience during actual use.

The principle behind the test is straightforward yet effective. The cylindrical pillow filled with feathers and down is pushed along the inclined plane by a bottom impact rod toward a top impact plate, compressing the sample with each impact. After each strike, the sample slides back to its original position, allowing the impact to be applied at different points around the pillow’s circumference. This repeated compression and impact cycle continues until a predetermined number of impacts is reached.

The performance of the fabric is assessed by measuring the amount of feathers and down that escape, extend out, or fall from the sample during the test. This provides a clear indication of the fabric’s resistance to drilling and lint loss, which are critical factors in maintaining the integrity and comfort of down products.

This testing machine is essential for manufacturers and quality control professionals who need to ensure that their down-filled products maintain their insulating properties and durability over time. By accurately simulating the stresses that fabrics endure, the Anti-drilling and Lint Tester helps improve product reliability and customer satisfaction.

Scope of application:

The impact method is used to determine the anti-drilling performance of fabrics, which is suitable for testing various down products, such as down quilts, down jackets, etc.

Product details:

The fabric to be tested is made into a cylindrical bag, filled with feathers, down or a mixture thereof. The sample bag is placed on the inclined plane, and the impact needle fixed on the movable plate reciprocates with the movable plate, while compressing and impacting the sample bag. Repeat the operation until a certain number of impacts are reached and then stop the test.

Test principle:

The test sample is a cylindrical pillow filled with a certain amount of feathers and down. During the test, the sample is pushed along the inclined plane by the bottom impact rod to the top impact plate, and the sample pillow is compressed. After one impact, the sample slides down along the track and returns to its original state. This step is repeated until the set number of impacts is reached. Since the extrusion range of the impact rod is greater than or less than the circumference of the sample pillow, the pillow will be squeezed at different locations. The anti-drilling performance of the sample is evaluated based on the total number of feathers and down that drill out, extend out and fall in the sample after a certain counting cycle.