Custom Solutions for Fabric Washing Shrinkage Testing

Blog 10 6 月, 2025

In the dynamic world of textiles and apparel, ensuring fabric quality and predicting how garments will perform after washing are critical. Shrinkage can lead to ill-fitting clothes, dissatisfied customers, and costly returns. That’s why precise and reliable washing shrinkage testing is non-negotiable for manufacturers, brands, and quality control labs.

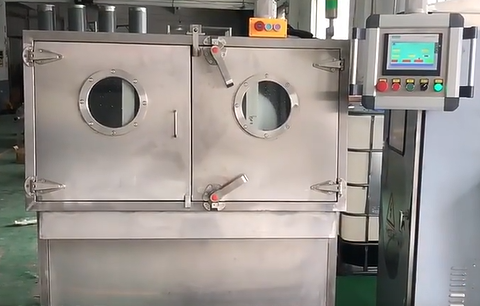

Our Fabric Washing Shrinkage Test Machine, built to meet stringent AATCC standards, is designed to be the cornerstone of your textile quality assurance. But we understand that “one size fits all” rarely works in a global, diverse industry. That’s why we specialize in providing customized solutions to perfectly align with your specific testing needs and operational workflows.

Your Unique Challenges, Our Tailored Solutions

Every textile business has distinct requirements. Whether you’re dealing with delicate silks, heavy-duty denims, performance activewear, or technical fabrics, precise control over the washing and drying parameters is essential. Here’s how we customize our Fabric Washing Shrinkage Test Machine to deliver exact solutions for our clients:

1. Tailored Program Configurations for Diverse Fabrics: Your product line demands varied testing protocols. Our machine comes with 10 pre-set laundry programs (including Regular, Normal, Bulky, Delicate, Soak, Super Wash), but we go further. We work with you to configure and fine-tune these programs or develop new ones based on your specific fabric compositions, weaves, and intended care instructions. This ensures that the testing conditions precisely mimic real-world consumer washing habits for your unique materials, guaranteeing accurate shrinkage predictions.

2. Precision Control Over Washing and Drying Cycles: Beyond basic temperature and water level, we offer advanced customization to meet niche testing demands:

Water Temperature and Grade Customization: While our machine offers 5 water temperature periods and 3 water grade periods, we can adjust these parameters to align with regional water hardness levels or specific care label requirements unique to your target markets.

Agitation and Washing Method Optimization: The Xtra Roll action agitator and robust washing method ensure thorough cleaning. For highly specialized textiles, we can explore nuanced agitator speeds and patterns to simulate particular washing forces, critical for assessing the stability of complex fabric constructions.

Sensing Drying System with Crease-Resist Optimization: The dryer’s sensing and quiet drying systems are excellent, but for delicate or performance fabrics where appearance retention is key, we can help you fine-tune cold air cycles and drying times to specifically minimize creasing, directly impacting your product’s final presentation.

3. Integrating with Your Quality Ecosystem: Our commitment to customization extends beyond the machine itself:

Data Integration and Reporting: While the touch panel offers intuitive control, we can explore solutions for integrating test data (shrinkage/elongation percentages, grading results) directly into your existing Quality Management Systems (QMS) or enterprise software. This streamlines data flow, reduces manual entry errors, and provides instant insights for faster decision-making.

Accessory Bundling for Turnkey Operations: We offer a range of optional AATCC accessories, including fluorescent detergent, standard companion wash cloths, non-fade marking pens, standard shrinkage dial gauges, and print rulers. We can curate a specific accessory package that provides a complete, ready-to-use testing solution tailored to your operational scale and specific AATCC test methods (e.g., AATCC 135 for dimensional changes or AATCC 124 for smoothness appearance).

Global Compatibility: With flexible power supply options (220V/50Hz standard, with 110V optional), we ensure the machine seamlessly integrates into your global production and testing facilities, regardless of geographical location.

Delivering Tangible Value to Your Business

By providing a customized Fabric Washing Shrinkage Test Machine solution, we empower our clients to:

Boost Product Quality: Consistently predict and control fabric shrinkage, ensuring garments maintain their intended fit and appearance after washing.

Reduce Costly Returns: Minimize customer dissatisfaction and returns stemming from unpredictable fabric performance.

Accelerate R&D and Product Development: Quickly validate new fabric constructions and finishes under precise, repeatable conditions.

Ensure Regulatory Compliance: Confidently meet and exceed demanding AATCC standards, crucial for market access and brand credibility.

Optimize Care Labeling: Provide accurate and reliable care instructions to consumers, enhancing product longevity and user experience.

In a competitive market where precision and reliability differentiate leaders, our ability to provide a tailored Fabric Washing Shrinkage Test Machine ensures you’re not just testing fabric—you’re securing your brand’s reputation for quality and performance. Let’s discuss how we can engineer the perfect solution for your textile testing challenges.