How Textile Water Evaporation Rate Testers Elevate Fabric Performance

New 18 6 月, 2025

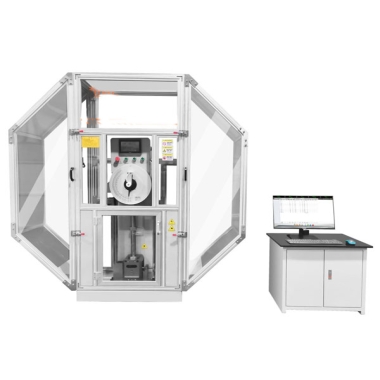

In today’s performance-driven world, textiles are no longer just about comfort or style; they’re engineered for functionality. Among the most sought-after features is quick-drying capability, a critical attribute for activewear, outdoor gear, and even everyday clothing. But how do manufacturers objectively measure this elusive property? Enter the Textile Water Evaporation Rate Tester, a sophisticated piece of equipment that’s demystifying the science of moisture management.

This innovative testing apparatus doesn’t just tell you if a fabric dries fast; it quantifies how fast, providing crucial data that drives product development and ensures consumer satisfaction.

https://standards-groups.com/textile-water-evaporation-rate-tester/

The Core Principle: Understanding Wicking and Evaporation

At its heart, quick-dry technology in textiles revolves around two key processes: wicking and evaporation.

Wicking: This is the fabric’s ability to draw moisture (like sweat) away from the skin and spread it across a larger surface area. Think of tiny capillaries in the fabric fibers pulling liquid along. This is achieved through engineered fiber structures, often using synthetic materials like polyester or nylon, which are inherently hydrophobic (water-repelling). These fibers, despite repelling water themselves, create microscopic channels that allow water to be drawn up by capillary action.

Evaporation: Once the moisture is spread across the fabric’s surface, the next crucial step is evaporation. This is where liquid water changes into water vapor and dissipates into the air. The faster this happens, the quicker the fabric dries. This process is heavily influenced by surface area, airflow, temperature, and humidity.

The Textile Water Evaporation Rate Tester specifically targets this second, critical phase: evaporation.

How the Tester Reveals Quick-Dry Secrets: A Deep Dive into the Technology

The Textile Water Evaporation Rate Tester, designed to rigorous standards like AATCC Test Method 201. AATCC Test Method 199. AATCC Test Method 200. and ASTM E96. provides an objective, repeatable, and highly accurate method to quantify a fabric’s drying speed. Here’s a breakdown of the ingenious technology at play:

Simulating Real-World Conditions: The system is engineered to mimic the actual environment a fabric experiences. Imagine sweat evaporating from fabric in contact with skin, or a damp garment drying in specific atmospheric conditions. The tester creates these controlled scenarios to provide relevant data.

Precision Weighing for Evaporation Rate: At the core of the measurement is an imported high-precision balance with an accuracy of 0.001g. A precisely cut fabric sample (e.g., 100mm x 100mm) is saturated with a known amount of water and then placed on the balance within a controlled environment. As water evaporates from the fabric, the sample’s weight decreases. The tester continuously monitors this minuscule weight change over time.

Controlled Environment and Airflow: While not explicitly detailed as an adjustable parameter for airflow, the “optimized structural design for precise positioning” and the general principles of evaporation testing imply a controlled environment where air movement, temperature, and potentially humidity are consistent. This consistency is vital to ensure that weight loss is solely due to evaporation from the fabric and not external variables.

Automated and Multi-Workstation Efficiency: The system boasts 6 independent workstations, allowing for simultaneous testing of multiple samples. This significantly boosts efficiency, crucial for R&D and quality control labs. A computer software upper-computer control system manages the entire process, allowing for flexible setting of weighing intervals (e.g., every minute or more frequently).

Real-time Data Acquisition and Analysis: As the test progresses, the software collects data in real time. It automatically calculates the evaporation rate (how many grams of water are lost per unit of time) and generates test result curves. These curves visually represent the drying process, showing the weight loss over time. The test typically terminates when the evaporation rate change does not exceed a specified threshold, like 1%, indicating the fabric is effectively dry.

Safety and Durability: Features like an “institutional self-locking function” prevent accidents during power failures, while “high-quality drive motors” ensure smooth, low-noise operation and durability. The robust construction ensures long-term reliability in laboratory settings.

The Impact: Driving Innovation and Trust

By providing quantitative data on water evaporation rates, the Textile Water Evaporation Rate Tester empowers manufacturers to:

Objectively Compare Fabrics: Move beyond subjective “feel” to hard data when evaluating quick-drying claims.

Optimize Fabric Design: Fine-tune fiber blends, weaves, and finishes to maximize wicking and evaporation performance.

Ensure Quality Control: Consistently meet performance specifications, reducing product returns and enhancing brand reputation.

Innovate New Materials: Develop next-generation textiles with superior moisture management properties for diverse applications.

In a competitive market where performance is paramount, this technology provides the scientific backbone for quick-dry claims, fostering innovation and building consumer trust one rapidly drying fabric at a time.