Leather flexural tester

Category:Fatigue Tester

Introduction

Standards

EN ISO 20344:6.6: Safety footwear leather flexing resistance.

I.U.P.10+20/I.U.P.20: International Union of Leather Technologists protocols for crease crack analysis.

UNI 4818: Italian standard for leather flex endurance.

DIN 53.351: German industrial standard for material bending fatigue.

UNE/I.U.P.20: Spanish national standard for protective footwear upper testing.

Product Advantages

Multi-Station Efficiency: 12-station configuration enables parallel testing of leather samples, reducing batch evaluation time by up to 75%.

Automated Operation: Pre-programmed cycle counter with auto-stop function eliminates continuous monitoring, enhancing lab productivity.

Temperature Control: Optional low-temperature variants (-20°C to ambient) simulate extreme climatic conditions for protective footwear testing.

Ergonomic Design: Bench-mounted unit with tool-free sample clamping and intuitive control panel for rapid setup.

Global Compliance: Meets critical standards for automotive interiors, safety footwear, and luxury leather goods.

Surface Finish Analysis: Detects micro-cracks and coating delamination in creased areas, critical for assessing wear in dress shoes and bags.

Product Features

Flexing Mechanism: Rotary bending arm applies 180° reciprocal motion to leather samples at 100 ±5 cycles/min.

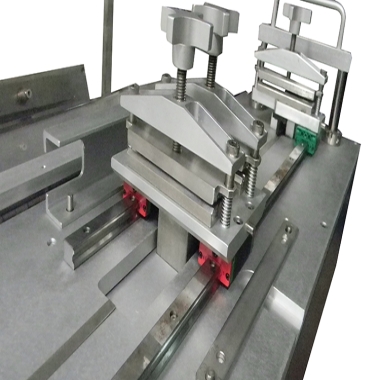

Sample Mounting: 12 independent clamps with adjustable tension screws accommodate leather strips (70×45 mm) and finished footwear uppers.

Digital Control System:

Programmable cycles (1–999.999) with pause/resume functionality.

Real-time cycle counter and failure alerts (e.g., stitch breakage, coating cracks).

Temperature Regulation:

Ambient to -20°C operation (low-temp models) with digital thermostat.

Insulated chamber minimizes condensation during cold testing.

Safety Features: Emergency stop button, over-cycle protection, and non-slip bench mount.

Technical Parameters

| Parameter | Specification |

|---|---|

| Work Stations | 6 or 12 (user-selectable) |

| Flexing Angle | 180° (reciprocal motion) |

| Cycle Speed | 100 ±5 cycles/min |

| Temperature Range | Ambient to -20°C (low-temp models) |

| Sample Dimensions | 70 × 45 mm (standard) |

| Power Supply | 220V/50Hz, 500W |

| Dimensions | 800 (W) × 600 (D) × 400 (H) mm |

| Net Weight | 65 kg (12-station model) |

| Data Output | USB port for cycle logs and failure timestamps |