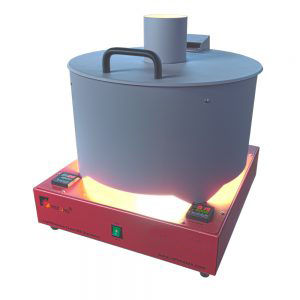

Sublimation Fastness Tester Scorch Tester

Category:Color Fastness Tester

Introduction

Introduction

Sublimation Fastness Tester is used for determination of color fastness performance to hot pressing ironing and dry heating (sublimation) for all kinds of dyeing and printing textile materials and textiles, and it can also be used for the test of textile resistance to chlorine damage, scorch, bleaching yellowing, sublimation color fastness test of disperse dyes, hot water fastness test of reactive dyes, dimensional stability at high temperature, etc.

Application

Printing and dyeing fabrics, textile auxiliary agents, and other areas of the textile and apparel.

Standards

GB/T 5718 Textiles color fastness test. P01: Colour fastness to dry heat (excluding heat pressing)

GB/T 6152 Textiles; tests for colour fastness to hot pressing

JIS L0879 Test methods for colour fastness to dry heat

JIS L0850 Tests for color fastness to hot pressing

ISO 105 P01Textiles; tests for colour fastness; part P01: colour fastness to dry heat (including hot pressing)

ISO 105 X11Textiles; Tests for colour fastness; Part X11 : Colour fastness to hot pressing

AATCC 117 Tests for color fastness to dry heat (no pressing)

AATCC 133 Tests for color fastness to high temperature (hot pressing)

M&S C13 Tests for color fastness to high temperature (hot pressing)

M&S C10 Dimensional stability test

Features

Up and down independent temperature control system, the use of PID temperature control program offers high temperature control accuracy and low heating efficiency; PT 100 temperature sensor configured;

Adjustable hinge connection design allows testing of different thickness materials. Able to ensure uniform pressure and heating distribution while testing thicker materials;

Timer configured is to preset the test time. Test time automatically starts when the upper pressing plate is pressing down. Configure the buzzer prompt to remind the end of the test;

Technical Parameters

| Heating plate size | 210mm×210mm |

| Heating plate material | Aluminum plate |

| Preheating time | custom |

| Pressure | 4kPa±1 kPa(full size) |

| Temperature control | Independent heating up and down |

| Temperature heating range | Ambient temperature-300°C |

| Temp control stability | ±1°C |

| Temp uniformity | ±1°C |

| Timer | Presetting time. Upper pressing plate down, automatic timing |

| Time-up Alarm | Buzzer alarm |

| Applicable test | Hot pressing, dry pressing and dimensional stability test |

| Power supply | 220V,50Hz |

| Dimension | W345mm×D520mm×H320mm |

| Weight | 12kg |