Unveiling the Tech Behind Precision Optics: Inside Our Advanced Camera Test Light Box

New 10 6 月, 2025

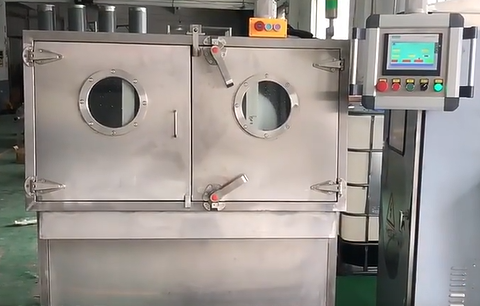

In the ever-evolving landscape of digital imaging, the clarity, sharpness, and color accuracy of cameras are paramount. From smartphone cameras to high-end surveillance systems, ensuring optimal performance relies on rigorous, standardized testing. Today, we’re taking a closer look at the advanced engineering that powers our Camera Test Light Box, a device at the forefront of optical calibration and quality assurance. This isn’t just a box; it’s a meticulously engineered environment designed to reveal the true capabilities of any camera.

The Science of Seeing: How Our Light Box Works

At its core, a camera test light box creates a controlled and consistent lighting environment where cameras can be evaluated against objective standards. Our latest model pushes these boundaries with several integrated cutting-edge technologies:

1. Uniform Illumination Control: Beyond Simple Brightness

The challenge in camera testing isn’t just making a light bright, but making it perfectly uniform across the entire field of view, regardless of the lens type. Our system achieves this with Bi-Directional LED Panels measuring 300mm x 400mm each. These aren’t just any LEDs; they’re precisely calibrated to offer a standard 6.500K color temperature, mimicking natural daylight, with optional ranges from 5.000K to 9.500K to simulate various conditions.

The secret to their uniformity lies in Hollow-Glass Bead Diffusion Technology. Traditional diffusers can create “hotspots” – areas of uneven brightness. By embedding hollow glass beads, our system reduces these hotspots by over 90%, ensuring that every pixel of the test chart receives consistent illumination. This is critical for accurate MTF (Modulation Transfer Function) analysis, which measures lens sharpness and contrast. Furthermore, the 360° Tilt Functionality of the panels allows for manual rotation, enabling optimal backlight setups that are crucial for specific testing scenarios.

2. Precision Positioning: Capturing Every Angle

Modern cameras boast everything from ultra-wide to powerful telephoto lenses, each with a unique Field of View (FOV) ranging from 70° to a sprawling 180°. Testing such diverse optics with a single setup requires sophisticated positioning. Our Camera Test Light Box integrates a Motorized Sliding Stage with ±50mm of precise travel. This allows the camera to be positioned at the exact distance from the test chart to fill the frame perfectly, regardless of its FOV. The stage operates on Linear Rails with 600mm of travel and an impressive 0.1mm resolution scale, ensuring repeatable and accurate placement. Quick-release clamps accommodate various camera mounts, making setup fast and efficient.

3. Modular Test Environment: Adaptability is Key

The ability to swap out test charts quickly and easily is essential for comprehensive camera evaluation. Our system features a Magnetic Chart System that securely holds two ISO 12233 charts (712mm x 400mm), vital for SFR (Spatial Frequency Response) testing, which determines lens resolution. This modularity also supports custom fisheye targets, catering to specialized optical systems.

4. Advanced Connectivity: Data at Your Fingertips

Seamless integration with external measurement systems and control software is non-negotiable in modern testing. Our light box includes an Integrated I/O Panel with pre-wired RS232. USB 3.0. and Ethernet ports. This enables direct camera tethering for image acquisition and provides Gigabit Ethernet for remote control via PC software, allowing engineers to manage tests and retrieve data from a central location.

Built for Performance and Longevity

Beyond its technical capabilities, the Camera Test Light Box is engineered for the rigors of industrial use. Its 130kg robust construction features a welded steel frame and anti-vibration leveling feet, ensuring stability during testing. The neutral gray enclosure is carefully chosen to minimize unwanted reflections that could skew MTF analysis.

In terms of sustainability, the unit is highly energy-efficient, consuming a maximum of 160W – an 80% reduction compared to traditional xenon light sources. The 50.000-hour LED lifespan not only cuts down on maintenance but also consistently maintains a CRI (Color Rendering Index) greater than 94 across all color temperatures, ensuring true-to-life color reproduction in test images.

Meeting Global Standards with Confidence

Our Camera Test Light Box is not just advanced; it’s compliant with the most respected international standards:

ISO 12233: Ensuring accurate SFR testing for lens resolution.

IEC 62679: Meeting photometric requirements for video camera performance evaluation.

CIE 15: Adhering to colorimetry standards for precise LED source spectral calibration.

By providing a meticulously controlled and adaptable testing environment, this new Camera Test Light Box empowers engineers and quality assurance teams to push the boundaries of optical performance, ultimately leading to clearer images and more reliable vision systems across industries.