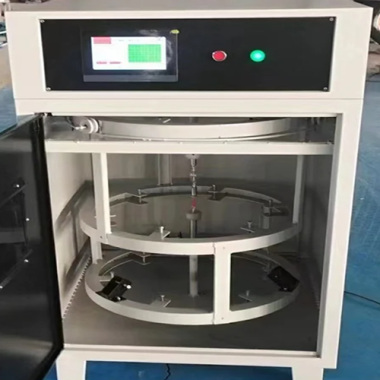

Water Vapor Permeability Tester

Category:Other

Introduction

This instrument is professionally applicable to the determination of water vapor transmission rate of plastic films, composite films, high barrier materials, back-sheets, sheeting, aluminum foils, waterproof materials, and other materials used in sanitary and medical industry. By testing the water vapor transmission rate, the technical indexes of materials could be controlled to meet the requirements for production.

Features

- The system is controlled by micro-computer with LCD, menu interface and PVC operation panel, which could conveniently export test data, test results and test curves

- Wide range and high-precision of automatic temperature control to support combinations of non-standard test conditions

- The system could be extended for the water vapor transmission rate test of finished package containers by special customization

- Reference film for fast calibration to ensure the accurate and universal test data

- Equipped with micro-printer and RS232 port for convenient data transfer

- Supports LystemTM Lab Data Sharing System for uniform management of test results and test reports

Principle

Under a certain test temperature, a constant humidity difference is generated between two sides of the test specimen. The water vapor permeates through the specimen into the dry side and then is taken to the sensor, where proportional electric signals will be generated. The water vapor transmission rate and other parameters can be obtained by analyzing and calculating these electrical signals.

Standards

This test instrument conforms to the following standards:

ISO 15106-3. GB/T 21529. DIN 53122-2. YBB 00092003

Applications

This instrument is applicable to the determination of water vapor transmission rate of:

Basic Applications

- Film

Including plastic film, plastic composite film, paper-plastic composite film, co-extruded film, aluminized film, aluminum foil, aluminum foil composite film, and many other films.

- Sheets

Includes engineering plastics, rubber and construction materials such as PP, PVC and PVDC.

- Paper and cardboard

Includes paper and cardboard, such as aluminum foil for cigarette packaging and Tetra Pak materials

- Packaging

Includes plastics, rubber, paper, paper-plastic composites, glass and metal packaging, such as Coke bottles, Tetra Pak materials, vacuum bags, metal three-piece cans, cosmetic and toothpaste tube packaging, and jelly cups.

Technical Specifications

| Specification | Details |

|---|---|

| Film Test | Approved |

| Test Range | 0.001 ~ 50 g/m2·24h (standard) 0.01 ~ 1000 g/m2·24h (optional) |

| Number of Specimens | 1 |

| Resolution | 0.1ppm |

| Temperature Range | 5°C ~ 95°C |

| Temperature Accuracy | ±0.1°C |

| Humidity Range | 0%RH, 2%RH ~ 98.5%RH, 100%RH (standard is 90%RH) |

| Accuracy | ±1%RH |

| Test Area | 38.48 cm2 |

| Thickness | < 1 mm (accessories required for thicker specimens) |

| Specimen Size | Φ100 mm |

| Carrier Gas | 99.999% High Purity Nitrogen (outside of supply scope) |

| Gas Flow | 100 mL/min |

| Gas Supply Pressure | ≥ 0.12 MPas |

| Port Size | 1/8 inch copper tubing |

| Instrument Dimension | 500 mm (L) x 400 mm (W) x 360 mm (H) |

| Power Supply | 220VAC 50Hz / 120VAC 60Hz |

| Net Weight | 36 kg |

Configurations

Standard Configurations

Instrument, Micro-printer, Constant Temperature Control Device, Precision Pressure Regulator for Nitrogen Cylinder, Porous Ceramic Tray, Desiccant, Round Sample Cutter and Vacuum Grease

Optional Parts

Professional Software and Communication Cable

Note

1. The gas supply port of the instrument is 1/8 inch copper tubing;

2. Customers will need to prepare for gas supply, distilled water, and salt reagent.