Thermal Protective Tester: Safety Guardian

New 17 10 月, 2025

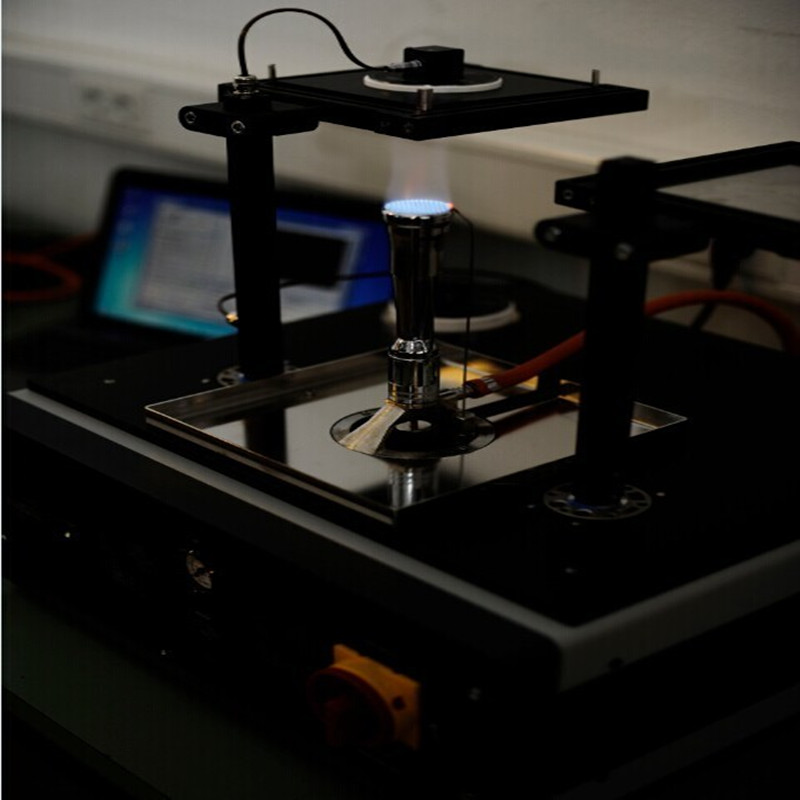

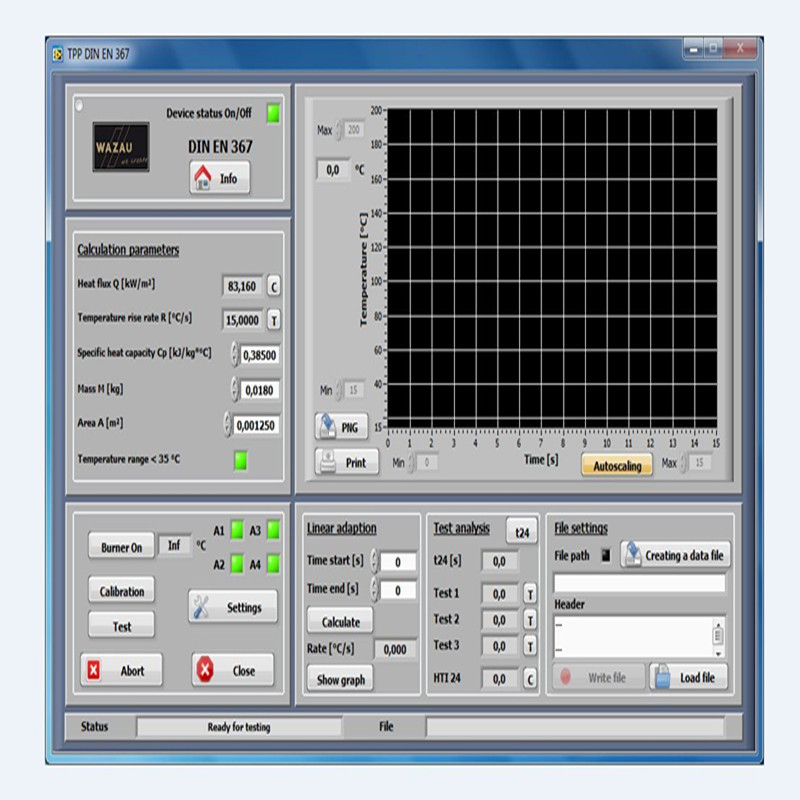

Tester: Precise “Assessor” for High-Temp Safety

In a world of evolving tech and complex scenarios, high-temp, flame, and heat-source hazards loom large. From industrial high-temp work to construction fires and electronic device overheating, ensuring materials, clothing, and equipment offer sufficient thermal protection is vital for personnel and property safety. The thermal protective performance tester acts as a precise “assessor,” simulating high-temp environments to test related items comprehensively, safeguarding safety.

Clothing Test: Quality Check for Protective Gear

In the clothing field, especially for protective apparel like fire-resistant suits, heat-insulating clothing, and high-temp workwear, performance directly impacts wearers’ safety in high-temp or fire environments. The tester conducts detailed tests on clothing materials. It measures flammability to judge how easily materials catch fire and burn. It assesses heat resistance to see if materials maintain structure and performance in high temps. It evaluates insulation to ensure materials block heat transfer effectively. It also determines thermal conductivity to understand how fast materials conduct heat, providing data for optimizing clothing design. For example, firefighters’ fire-resistant suits undergo strict testing to ensure reliable thermal protection during firefighting.

Fire Material Test: Strengthening Building Fire Safety

The quality of building, insulation, and fire-fighting materials is crucial for building and facility fire safety. The thermal protective performance tester simulates fire-related high-temp conditions to test the fire resistance of these materials. By measuring indicators like burning characteristics, thermal decomposition, and insulation effects in high temps, it assesses whether materials can effectively prevent fire spread during fires, buying precious evacuation and rescue time for buildings. For instance, fire-resistant and heat-insulating materials used in high-rise buildings are tested to ensure they play a good fire-insulating role in fires, protecting lives and building structures.

Protective Gear Test: Securing Worker Safety

In high-temp work environments, workers rely on various personal protective gear. The tester can evaluate the performance of fire masks, heat-insulating gloves, and fire-resistant boots. For fire masks, it tests filtration and sealing performance in high-temp and flame environments to ensure clean and safe air for workers. For heat-insulating gloves, it measures heat insulation and flexibility to prevent burns while allowing flexible operations. For fire-resistant boots, it assesses heat resistance, anti-slip, and foot protection to safeguard workers’ feet. In the steel smelting industry, workers wearing tested protective gear can significantly reduce risks in high-temp environments.

Electrical Equipment Test: Preventing Electronic Overheating

With the wide use of electronic devices, overheating issues in electrical equipment and electronic components under high-temp conditions are a growing concern. The thermal protective performance tester simulates high-temp conditions to test electrical equipment and components. By measuring indicators like operational stability, electrical performance changes, and heat dissipation effects in high temps, it ensures normal operation and prevents accidents like equipment damage, short circuits, and even fires caused by overheating. In data centers, where numerous servers and electronic devices operate continuously, testing helps detect potential heat issues early and take appropriate heat dissipation measures to ensure smooth operation.

Material R&D: Driving Thermal Material Innovation

Material scientists and researchers aim to develop more efficient thermal protective materials to meet increasing safety demands. The tester serves as an important research tool. Researchers can use it to assess the thermal protective performance of new materials. By comparing performance data of different materials in high-temp environments and analyzing the relationship between material structure, composition, and thermal protection performance, they can conduct targeted material modification and optimization. For example, in developing new thermal protective materials for aerospace, repeated testing and research with the tester help improve materials’ high-temp resistance and insulation performance, supporting aerospace development.

Product Certification: Ensuring Compliance with Safety Standards

In some industries like fire protection, power, and chemicals, products must meet specific thermal protective performance standards and regulations. The thermal protective performance tester is crucial for product certification and compliance testing. It can strictly test products to ensure they meet relevant requirements. Only products that pass testing and obtain certification can enter the market, safeguarding consumer rights and safety. For example, fire protection products must undergo testing and meet national fire protection standards before being used, providing reliable protection for fire fighting and evacuation.

Future Outlook: Continuous Development for Safety

As technology advances and safety requirements in various industries rise, the thermal protective performance tester will keep evolving. It may feature higher testing accuracy and a wider testing range to simulate more complex and extreme high-temp environments. The application of intelligent and automated technologies will also make the testing process more efficient and convenient. The tester will continue to play a vital role in various fields, contributing to personnel safety, reducing fire risks, and promoting industry development as an indispensable “safety guardian” in the high-temp protection field.