TPP Tester: Precision in Safety

New 27 10 月, 2025

In high-risk industries like petrochemicals, firefighting and rescue, and power maintenance, protective clothing is the ultimate armor protecting workers’ lives. As an innovative leader in safety testing, Standard Group’s TPP protective clothing performance tester, with its precise, intelligent, and standardized testing capabilities, provides comprehensive technical support for protective clothing R&D, production, and quality certification.

TPP: Measuring Safety Scientifically

The TPP value (Thermal Protective Performance) is a core indicator for measuring the thermal insulation performance of protective clothing. It is tested in a simulated fire environment using both radiant and convective heat.

The TPP test principle is based on international standards (such as NFPA 1971 and ISO 6942). The time required to induce second-degree burns is measured by placing the fabric under convective and radiant heat sources. The time required to induce second-degree burns is then multiplied by the exposure energy to obtain the TPP value.

The calculation formula is: TPP = t × q

where q is the specified radiant heat flux (typically 84 kW/m²) and t is the time required to induce second-degree burns (in seconds). The higher the TPP value, the better the thermal protection performance of the thermal protective clothing, and the higher the protection provided to the body.

Tech Breakthrough: Reproducing Extreme Heat

The Standard Group’s TPP protective clothing performance test device has achieved three major technological breakthroughs, ensuring the accuracy and reliability of test results.

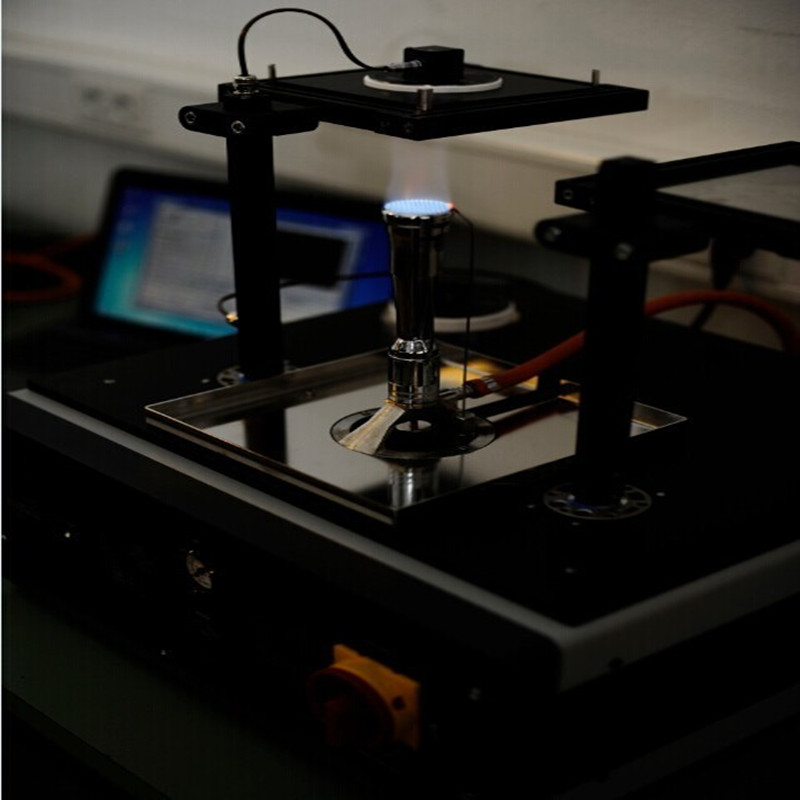

Dual Heat Source Simulation System: Integrates a radiant heat source (adjustable from 10-80kW/m²) and a convective heat source (propane flame), accurately reproducing the complex thermal environment of a fire scene and fully simulating real-world fire conditions.

High-Precision Sensor Array: Utilizes imported thermocouples and heat flow meters for real-time monitoring of heat flux, temperature transfer rate, and simulated skin burn severity. Data error is kept within 2%, ensuring accurate measurement results.

Intelligent Temperature Control Algorithm: Utilizes PID closed-loop control to ensure heat source stability, prevent temperature fluctuations from interfering with test results, and provide a reliable testing environment.

Innovative Design: Multi-Scenario & Smart

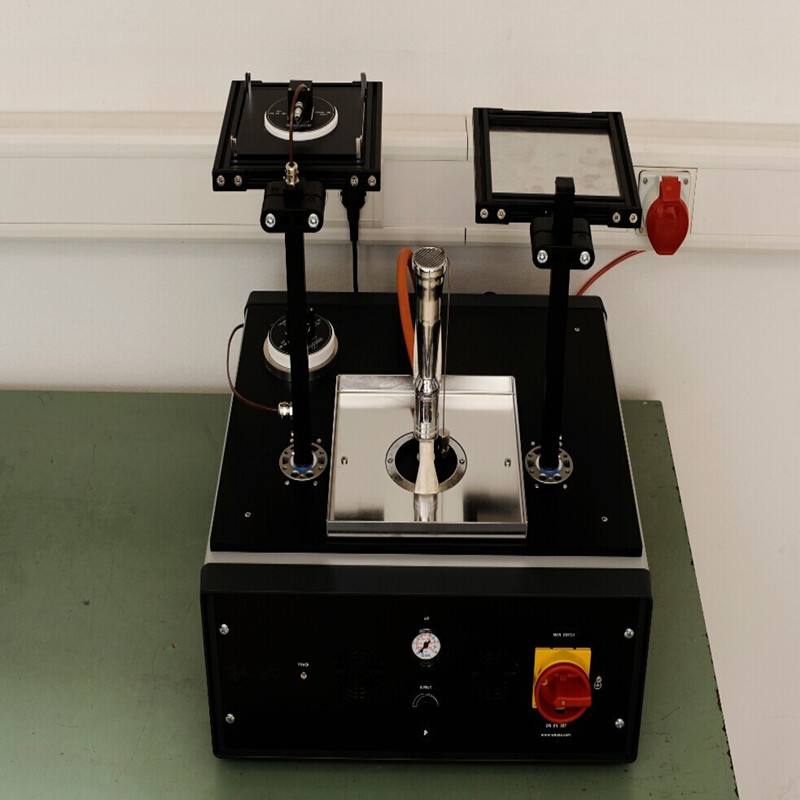

The STD-TPP test device features a modular design, supporting rapid switching between multiple test modules for scenarios such as radiant heat, flame contact, and molten metal splash, adapting to different protective clothing types (fire suits, arc protection suits, industrial heat protection suits, etc.).

The device offers automated operation, enabling one-click initiation of the test process. Data is automatically collected and a visual report is generated, with bilingual export support in Chinese and English, meeting global certification requirements.

In terms of safety, the test chamber is equipped with a high-temperature tempered glass observation window, an emergency braking system, and an exhaust gas purification device to fully ensure operator safety and environmental friendliness.

Moisture Impact: TPP Performance Insights

The fire scene environment in which firefighters operate is not a dry one. Human perspiration and firefighting water can cause clothing to absorb moisture. The STD-TPP test device can accurately measure the impact of moisture on thermal protection performance.

Research has shown that under conditions of combined heat transfer from strong radiation and convection (82.21 kW/m²), moisture improves the thermal protection performance of single-layer fabrics. When water vapor evaporates at high temperatures and reaches the surface of human skin, it can cause burns, but it also dissipates a significant amount of heat.

Experimental data shows that for every 1% increase in moisture content, the second-degree burn duration increases by 0.062 seconds and the TPP value increases by 0.072 kJ/cm². When the moisture content is less than 50%, the thermal protection performance of moist fabrics is superior to that of dry fabrics.

Compliance: Meeting Global Test Standards

The Standard Group’s TPP thermal protective clothing test device strictly adheres to international testing standards, including GB 8965.1-2009 “Protective Clothing – Flame-Retardant Clothing,” GA 10-2014 “Protective Clothing for Firefighters,” NFPA 2112. NFPA 1971. ISO 17492. and many other domestic and international standards.

The device accurately measures the thermal protection coefficient (TPP) and displays the time-temperature curve on a computer, providing intuitive and comprehensive test data output, helping users gain a deeper understanding of the material’s thermal protection performance.

The specimen’s irradiated area reaches 100 cm² ± 0.01 cm². The heat flux range for the radiant heat source is 10-50 kW/m², and the heat flux range for the convective heat source is 10-50 kW/m². The total heat flux is adjustable from 50 kW/m² to 100 kW/m².

The standard TPP test device not only serves firefighting uniform manufacturers but is also widely used in high-risk industries such as the petrochemical industry and power maintenance. With the continuous emergence of new materials and technologies, Standard Group will continue to innovate and iterate thermal protection testing technology, providing smart solutions made in China to the global safety and protection industry.