Tribometer Principles & Types

New 4 11 月, 2025

1. Core Measurement Principles

Static Friction Measurement

Static friction coefficient quantifies the minimum force required to initiate movement between two surfaces. Common methods include:

Inclined Plane Method: A weighted sled placed on a tilted sample begins sliding at a specific angle. The tangent of this angle gives the maximum static friction coefficient, indicating how easily surfaces start moving relative to each other.

Horizontal Pull Method: Measures the resistance when applying lateral force to initiate motion. This peak resistance determines the maximum static friction. This method can also track kinetic friction during sustained movement.

Kinetic Friction Measurement

Kinetic friction coefficient measures continuous resistance during relative motion. Specialized equipment uses:

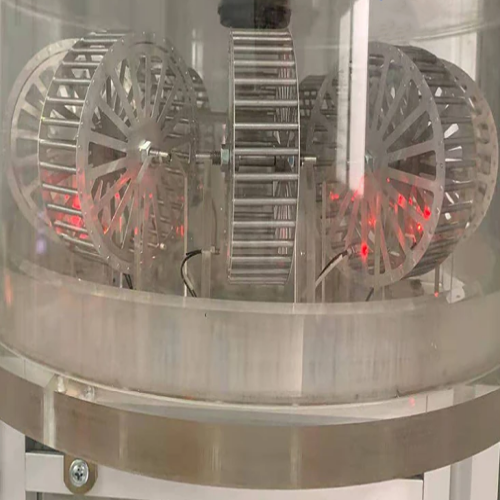

Rotational Type: Simulates continuous circular motion between surfaces

Reciprocating Type: Simulates linear back-and-forth motion

Both methods slide standardized counterpart materials against samples under controlled conditions.

2. Contact Type Selection

Point Contact

Configurations: Ball-on-Disc, Ball-on-Plane

Advantage: Concentrated stress enables rapid wear screening

Consideration: Wear-induced contact area changes may affect long-term accuracy

Line Contact

Configurations: Ring-on-Block, Pin-on-Block

Characteristics: Rotational testing with linear/curved contact interfaces

Primary Use: Particularly effective for lubricant performance evaluation

Surface Contact

Configurations: Plate-on-Block (reciprocating), Pin-on-Disc, Thrust Washer (rotational)

Advantage: Distributed stress mimics real-world conditions, ideal for durability testing

Application: Provides stable data for wear resistance and material longevity assessment

Key Takeaways

Selecting appropriate tribometer configurations depends on specific testing objectives—whether evaluating initial movement resistance (static) or continuous operation performance (kinetic), and whether seeking accelerated testing (point contact) or realistic simulation (surface contact).

We can recommend optimal testing methodologies based on your particular material evaluation requirements.