High temperature vacum friction & wear tester

Category:Other

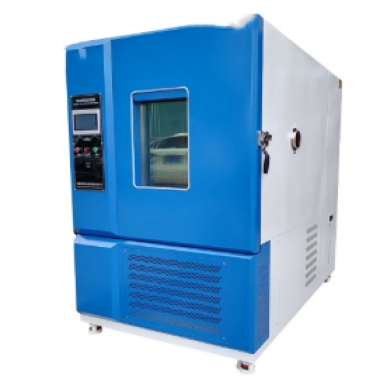

Introduction

The High Temperature Vacuum Friction & Wear Tester is a precision testing instrument designed to evaluate the friction and wear characteristics of materials under high temperature and vacuum conditions. With a sophisticated design and versatile functionality, it can simulate a variety of real-world conditions, providing reliable experimental data for materials science, aerospace, automotive, and industrial applications.

The instrument accurately measures friction force, wear depth, and wear track profiles, enabling researchers and engineers to understand material behavior under extreme environments.

Applications

Materials Science Research

Simulates high-temperature vacuum conditions to explore friction and wear mechanisms.

Provides experimental data for theoretical studies and material development.

Aerospace Applications

Evaluates wear resistance of aerospace materials in extreme operating environments.

Supports component selection, design optimization, and reliability assessment.

Automotive Industry

Tests high-temperature vacuum friction and wear properties of engine components and specialized parts.

Provides data for improving durability, performance, and lifetime of automotive components.

Other Industrial Applications

Metallurgy, chemical, and energy industries often encounter friction and wear under high-temperature vacuum.

Supports quality control, production optimization, and material selection.

Applicable Standards

The High Temperature Vacuum Friction & Wear Tester is compatible with multiple international and industry standards, ensuring reliable and comparable test results:

ASTM Standards – Specific methods for high-temperature and vacuum friction/wear testing, including loading, test temperature, vacuum degree, and data recording.

ISO Standards – Provides a global framework for conducting high-temperature vacuum friction and wear tests.

Industry & Enterprise Standards – Custom protocols may be applied for specific materials, environments, or organizational requirements.

Note: Users should select standards based on material type, application, and testing purpose to ensure accurate and reproducible results.

Technical Parameters

| Parameter | Unit | Min | Max | Note |

|---|---|---|---|---|

| Pin/Ball Diameter | mm | 3 | 12 | Round or square pins |

| Wear Track Diameter | mm | 15 | 70 | Disk diameter 100 mm |

| Rotational Speed of Disk | rpm | 1 | 2000 | 0.1 rpm minimum count |

| Positive Load | N | 0 | 60 | 50 mN minimum count |

| Friction Force | N | 0 | 20 | 5 mN minimum count |

| Temperature | ℃ | Ambient | 800 | 1°C minimum count |

| Wear Test Range | μm | 0 | 2000 | 0.1 μm minimum count |

| Disk Vibration | Degrees | 0 | 0 | 1 degree minimum count |

| Angular Frequency | Hz | 0.1 | 5 | – |

| Preset Timer | Hr/Min/Sec | 0 | 99/59/59 | – |

| Power Supply | V/kVA/Ph/Hz | 230/10/1/50 | – | – |