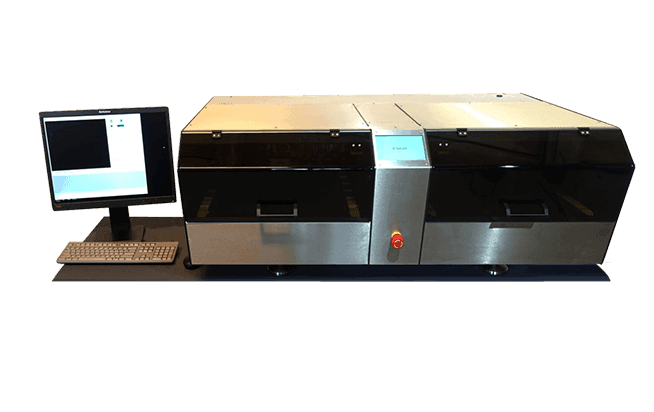

Multifunctional electronic fabric strength meter

Category:Other

Introduction

The Multifunctional Electronic Fabric Strength Tester is a high-precision instrument designed for comprehensive textile material testing, including woven, non-woven, and composite fabrics. Equipped with advanced digital control and intelligent data management, the instrument provides accurate and reproducible measurements for tensile, tear, peel, burst, seam slippage, elastic recovery, creep, and yarn strength tests.

This versatile device supports multiple testing modes, enabling research, production, and quality control applications in the textile and apparel industry.

Application Scope

The tester is suitable for a wide range of fabric and textile testing applications:

Constant speed tensile testing

Constant time tensile testing

Constant elongation tensile testing

Constant load tensile testing

Tear resistance testing

Peel strength testing

Burst strength testing

Seam slippage resistance testing

Elastic recovery testing

Creep performance testing

Yarn strength testing

It is ideal for R&D laboratories, manufacturing quality control, and material evaluation.

Compliance Standards

Chinese Standards:

GB/T3917.2/3/4/5

FZ/T01030, FZ/T60006, FZ/T01031, FZ/T70006

GB/T3923.1/2, GB/T13772.1/2/3, GB/T13773.1/2

FZ/T01034, FZ/T70007, FZ/T01085, FZ/T80007.1

GB/T19976, FZ/T20019, GB/T23318, GB/8688

International Standards:

ISO3303, ISO9073-4, ISO13934-1/2, ISO13935-1/2, ISO13936-1/2/3

ASTM D434, ASTM D4964, ASTM D1683, ASTM D5034, ASTM D2261, ASTM D5035, ASTM D2724, ASTM D5587, ASTM D3936, ASTM D5733

JIS L1096

Ensures international comparability and compliance with global textile testing requirements.

Instrument Features

1. Advanced Drive System

AC servo motor with full digital speed closed-loop control

High-speed stability and precise positioning accuracy

Wide speed range with digital setting for gauge length and stretching speed

2. Intelligent Data Management

High-speed USB interface for direct computer connection

Real-time and historical data display, test reports, and graphical analysis

Supports database creation and long-term data management

3. Customizable Clamping Systems

Optional clamps including pneumatic clamps for diverse specimen types

Modular design enables quick reconfiguration for multiple testing scenarios

Technical Parameters

| Parameter | Specification |

|---|---|

| Control Mode | Microcomputer control |

| Average Number of Groups | 2–30 times (calculates warp-direction average; LCD display and printout for latitudinal average) |

| Stylus Force Range | 1000 N, 3000 N, 5000 N, 10000 N (optional) |

| Maximum Elongation | Up to 350% at 200 mm gauge length |

| Return Rate | 2 mm/min – 1000 mm/min |

| Gauge Length | Adjustable within 25–500 mm |

| Stretching Rate | 2 mm/min – 1200 mm/min, arbitrary value |

| Timed Stretching | 20 s ± 3 s, 30 s ± 5 s (optional) |

| Maximum Set Number of Stretches | 99 times |

| Weight | 20 kg |

| Power Supply | AC 220 V, 50 Hz |

| Dimensions (L × W × H) | 70 cm × 60 cm × 170 cm |