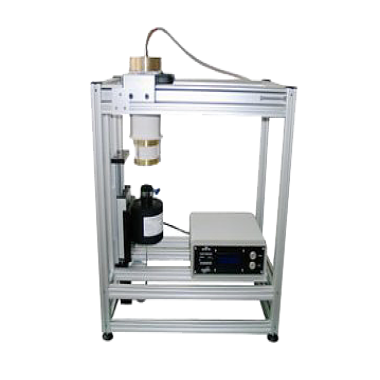

Shoe heat insulation testing machine — sand bath

Category:Other

Introduction

Standard

GB/T 20991: Determines thermal insulation of safety shoe soles under simulated hot surface exposure.

EN ISO 20344: European standard for personal protective equipment (PPE) footwear thermal resistance testing.

Product Advantages

1. Accredited Thermal Performance Analysis

Dual-Standard Compliance: Meets stringent Chinese and EU regulations for global market access.

Traceable Calibration: NIST-traceable temperature verification with certificate.

2. Realistic Testing Conditions

Granular Heat Transfer: Simulates contact with hot surfaces (e.g., asphalt, metal) via industrial-grade silica sand.

Steel Ball Simulant: Replicates foot pressure distribution inside the shoe.

3. Safety-First Design

Insulated Enclosure: Heat-resistant acrylic shield with interlock safety switches.

Emergency Cooldown: Auto-shutoff at 60°C surface temperature.

4. Precision Control

PID Temperature Regulation: ±0.5°C stability across 50–200°C range.

Fast Response Probes: K-type thermocouples with 0.1°C resolution.

5. User-Centric Workflow

Plug-and-Play Sensors: Pre-calibrated probes with color-coded connectors.

Intuitive Interface: 4.3” TFT display with real-time temperature curves.

Product Features

Sand Bath System:

Heated Plate: 300mm × 300mm aluminum plate with 50mm silica sand layer.

Uniform Heating: Embedded cartridge heaters with thermal diffusers.

Temperature Control:

PID controller with auto-tuning for rapid setpoint convergence.

Over-temperature alarm with 5°C differential protection.

Sensing Suite:

2 × K-type thermocouples for sand bath and shoe interior.

1.5m cable length for flexible probe placement.

Safety Systems:

Category II electrical safety certification (EN 60529).

Residual current device (RCD) for operator protection.

Software Bundle:

ThermShoe Pro™: Auto-calculates thermal gradient (°C/min) and insulation index.

Cloud PPE: Remote monitoring for global R&D teams.

Accessories & Options

Standard Kit:

100 × 50g calibration steel balls (316L stainless).

2 × K-type thermocouples with color-coded connectors.

Software Add-Ons:

Batch Processor: Queue 24/7 unattended testing.

API Integration: Connect to MATLAB/Python for custom analytics.

Safety Upgrades:

Explosion-proof enclosure for volatile environments.

HEPA filtration for particle-sensitive labs.

Calibration Services:

Annual recalibration with NIST-traceable certificate.

Consumables:

10L Replacement silica sand (high-purity, 0.5–1mm grain).

1L Thermal paste for sensor calibration.

Technical Parameters

| Specification | Details |

|---|---|

| Heat Plate Dimensions | 300mm (L) × 300mm (W) × 50mm (H) |

| Temperature Range | 50°C to 200°C (adjustable in 1°C increments) |

| Control Accuracy | ±0.5°C (±0.1°C with calibration kit) |

| Sand Layer Depth | 50mm (industrial silica sand included) |

| Steel Ball Load | 5kg total (100 × 50g balls, 316L stainless) |

| Power Supply | 220V/50Hz (110V/60Hz available) |

| Dimensions (W×D×H) | 400mm × 400mm × 600mm |

| Weight | 35 kg (net) |