Anti-crack fatigue tester

Category:Other

Introduction

Product Introduction & Applications

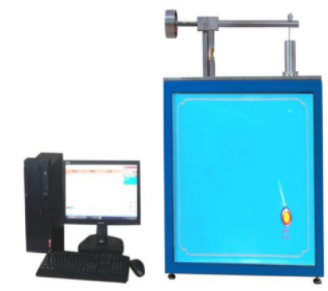

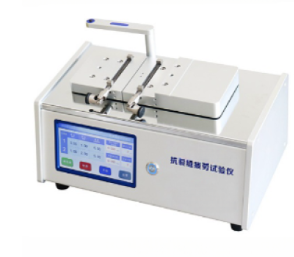

The Anti-Crack Fatigue Tester is designed to evaluate the fatigue resistance and crack propagation characteristics of materials under cyclic loading conditions. By simulating repeated stress and strain, it measures how materials behave under long-term fatigue and helps identify potential failure points.

This tester is widely used in:

Material Research & Development: Assessing durability and fatigue properties of metals, plastics, composites, and coatings.

Quality Control: Ensuring product consistency and performance under cyclic stress.

Industrial Testing: Supporting aerospace, automotive, and construction industries with fatigue evaluation data.

Standards

HG/T 4343 — Fatigue Testing of Metals

ASTM E739 — Strain-Controlled Fatigue Testing of Materials

ASTM E647 — Measurement of Fatigue Crack Growth Rates

GB/T 3075 — Fatigue Testing of Metallic Materials

Technical Parameters

| Parameter | Details |

|---|---|

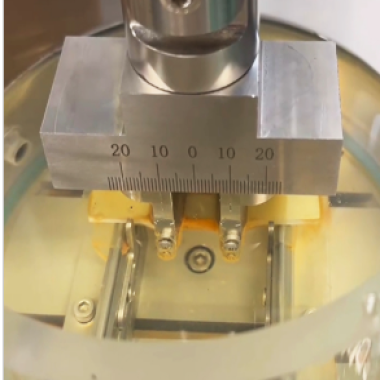

| Maximum Moving Distance | 10 mm (adjustable) |

| Moving Distance Accuracy | 0.01 mm |

| Operating Speed | 0.01–20 mm/min (adjustable) |

| Tensile Measurement Range | 10–250 N (model-dependent) |

| Test Plate Size | 120×80×10 mm or 120×40×10 mm |

| Power Consumption | Approximately 80 W |

| Dimensions & Weight | Compact and easy to operate; varies by model |

Usage Notes

Ensure the test specimen is securely clamped before starting the test.

Select appropriate maximum moving distance and speed according to the material and standard being tested.

Avoid exceeding the tensile measurement range to prevent instrument damage.

Regularly calibrate the tester to maintain measurement accuracy.

Operate the machine in a stable, vibration-free environment to ensure reliable test results.

FAQ

What materials can be tested with this machine?

It can test metals, plastics, composites, coatings, and other materials requiring fatigue evaluation.

How do I adjust the moving distance and speed?

Both the maximum moving distance and operating speed are adjustable via the instrument’s control interface.

Can it automatically record data?

Yes, the machine is usually equipped with a data recording and analysis system for real-time monitoring.

What is the typical accuracy of movement during testing?

The moving distance accuracy is generally 0.01 mm, ensuring precise fatigue testing.

How should the tester be maintained for long-term use?

Regularly calibrate the sensors, keep the machine clean, and operate it in a stable environment to maintain performance.