Glow Wire Tester: Applications and Standards

Blog 3 12 月, 2025

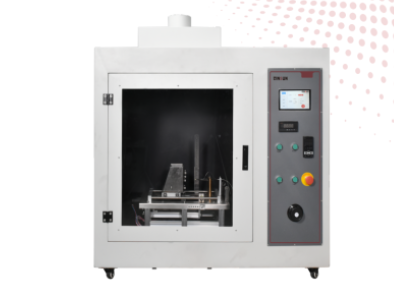

The Glow Wire Tester (F242) is a precision instrument designed to assess the flammability and ignitability of electrical and electronic components by simulating thermal stress conditions caused by hot components, overloaded resistors, or other short-term heat sources. Widely applied across household appliances, industrial and domestic lighting, electrical insulation materials, and other electrical products, it helps manufacturers predict fire hazards, control production quality, and verify product performance.

Product Applications

Fire Hazard Assessment of Electrical Materials

During normal use, electrical materials may reach excessive temperatures due to overload, short circuits, poor contact, or other faults. The Glow Wire Tester simulates these conditions by applying controlled thermal stress, allowing evaluation of a sample’s susceptibility to ignition or combustion.

Light-Off and Flammability Testing

The instrument heats a wire of specified material and shape to the target temperature (550°C–960°C) and maintains it for 60 seconds. The sample is then exposed vertically under a defined load (1.0 N) for 30 seconds. Observing the sample’s reaction provides precise data on light-off properties, flammability, and the flammability index of solid insulating materials.

Performance Verification of Electrical Products

The tester is ideal for evaluating household appliances, electronic components, printed circuit boards, insulating materials, and other flammable components. It is also widely used in quality control, third-party testing laboratories, product development, and safety verification.

Flame Retardant Testing

It evaluates flame-retardant properties for insulated enclosures, switch panels, and other electrical materials, providing critical insights for compliance with national and international fire safety standards.

Standards Compliance

The Glow Wire Tester adheres to numerous international and national standards, including:

ASTM D6194-03 / ASTM D6194

IEC 60695-2-10:2021 / IEC 60335 / IEC 60695-2-1 / IEC 60695-2-11 / IEC 60695-2-12 / IEC 60695-2-13

UL 746A

VDE 0620

GB/T 5169.10-2006 / EC 60695-2-10-2013

GB/T 5169.11-2006 / IEC 60695-2-11-2000

GB/T 5169.12-2006 / IEC 60695-2-12-2000

GB/T 5169.13-2006 / IEC 60695-2-13-2000

These standards cover glowing-wire methods for flammability testing of solid insulating materials and finished electrical and electronic products.

Key Features

Transparent Safety Door: Heat-resistant glass window allows observation of the test without interference from external conditions.

Automatic Heating and Exhaust System: Programmable glowing-wire heating and contact position control with built-in lighting and exhaust.

Intelligent Touch Screen: 7-inch color LCD panel for precise control, monitoring, and data display.

Stepping Motor Control: Ensures accurate and adjustable moving speed of samples, allowing observation of flame height with integrated flame ruler.

Sample Rack Design: Removable sample holder for easy loading, cleaning, and efficient operation.

Technical Parameters

| Parameter | Details |

|---|---|

| Test Cabinet Size | 885 × 580 × 1000 mm |

| Effective Test Volume | ≥0.5 m³ |

| Glowing Wire Material | ¢4 mm Ni/Cr (80/20) |

| Test Temperature | Room temperature ~ 999°C (adjustable) |

| Glowing Time | 0–99 s (adjustable) |

| Sample Load | 1.0 N ± 0.1 N |

| Test Speed | 10–25 mm/s (adjustable) |

| Glowing Depth | 0–9 mm (presettable) |

| Temperature Sensor | Armored K-type thermocouple ¢0.5 mm, -200–1300°C, ±1°C |

| Control | 7-inch intelligent touch screen |

| Power Supply | AC 220V, 50Hz |

| Weight | 90 kg |

The Glow Wire Tester is an essential tool for manufacturers, laboratories, and testing organizations that need reliable, precise assessment of electrical and electronic product safety. Its compliance with global standards ensures accurate fire hazard prediction and material performance verification.