Fabric Strength Meter Applications and Standards

Blog 3 12 月, 2025

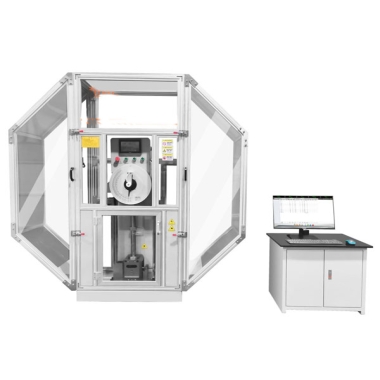

The Fabric Strength Meter is a precision instrument designed for testing the mechanical properties of textile materials, including woven and non-woven fabrics. It supports a wide range of tests such as tensile, tear, burst, seam slippage, peel, elastic recovery, and creep performance. This makes it an essential tool for textile manufacturers, laboratories, and quality control departments to ensure product quality, durability, and compliance with international standards.

Compliance Standards

Chinese Standards with Full Names:

GB/T 3917.2-2008: Textile – Determination of Breaking Force and Elongation – Strip Method

GB/T 3917.3-2008: Textile – Determination of Breaking Force and Elongation – Grab Method

GB/T 3917.4-2008: Textile – Determination of Breaking Force and Elongation – Strip Method for Warp and Weft

GB/T 3917.5-2008: Textile – Determination of Breaking Force and Elongation – Strip Method for Bias

FZ/T 01030-2008: Woven Fabrics – Determination of Breaking Strength and Elongation

FZ/T 60006-2008: Non-Woven Fabrics – Determination of Breaking Strength

GB/T 3923.1-2008: Textile – Tear Strength – Ball Method

GB/T 3923.2-2008: Textile – Tear Strength – Elmendorf Method

FZ/T 01031-2008: Woven Fabrics – Determination of Seam Strength

FZ/T 70006-2008: Woven Fabrics – Determination of Strip Tensile Strength

GB/T 13772.1-2008: Fabrics – Determination of Tensile Properties

GB/T 13772.2-2008: Fabrics – Determination of Tensile Properties

GB/T 13772.3-2008: Fabrics – Determination of Tensile Properties

FZ/T 01034-2008: Woven Fabrics – Determination of Tear Strength

FZ/T 70007-2008: Woven Fabrics – Determination of Tear Resistance

GB/T 13773.1-2008: Fabrics – Determination of Seam Slippage Resistance

GB/T 13773.2-2008: Fabrics – Determination of Seam Slippage Resistance

FZ/T 01085-2008: Woven Fabrics – Determination of Yarn Strength

FZ/T 80007.1-2008: Fabrics – Determination of Creep Behavior

GB/T 19976-2005: Determination of Fabric Elastic Recovery

FZ/T 20019-2008: Non-Woven Fabrics – Determination of Burst Strength

GB/T 23318-2009: Determination of Fabric Peel Strength

GB 8688-2008: Test Methods for Sewing Thread Strength

International Standards

ISO 3303: Textiles – Determination of Maximum Force and Elongation at Break

ASTM D434: Standard Test Method for Breaking Strength and Elongation of Textile Fabrics

ASTM D4964: Standard Test Method for Tearing Strength of Fabrics by the Tongue (Single Rip) Method

ISO 9073-4: Textiles – Nonwovens – Determination of Tear Resistance

ASTM D1683: Standard Test Method for Failure in Sewn Seams of Woven Fabrics

ASTM D5034: Standard Test Method for Breaking Strength and Elongation of Textile Fabrics (Grab Test)

ISO 13934-1/2: Textiles – Tensile Properties of Fabrics

ASTM D2261: Standard Test Method for Tearing Strength of Fabrics

ASTM D5035: Standard Test Method for Breaking Force and Elongation of Textile Fabrics (Strip Method)

ISO 13935-1/2: Textiles – Seam Tensile Properties

ASTM D2724: Standard Test Method for Elastic Recovery of Textiles

ASTM D5587: Standard Test Method for Creep of Fabrics

ISO 13936-1/2/3: Textiles – Determination of the Elastic Recovery of Fabrics

Applications

The Fabric Strength Meter is ideal for evaluating:

Constant speed, time, elongation, and load tensile properties

Tear resistance of woven and non-woven fabrics

Peel strength

Burst strength

Seam slippage resistance

Elastic recovery and creep performance

Yarn strength

It is widely used in textile production, garment R&D, quality control laboratories, and material certification centers, helping manufacturers improve durability, optimize fabric quality, and ensure compliance with international regulations.

Key Features

1. Advanced Drive System

AC servo motor with full digital speed closed-loop control

High speed stability, wide speed range, precise positioning

Digital settings for gauge length and stretching speed

2. Intelligent Data Management

High-speed USB interface for direct PC connection

Real-time and historical data display

Test report generation with charts and graphs

Supports database creation for long-term tracking

3. Customizable Clamping Systems

Optional pneumatic or mechanical clamps

Modular design for quick configuration changes

Advantages

High precision: Ensures reliable and repeatable results

Multi-functional: Supports multiple testing modes in one instrument

User-friendly: Real-time data display simplifies workflows

Flexible: Adapts to different fabrics and specimen shapes

Compliance-ready: Meets both Chinese and international textile standards

Disadvantages

Requires trained personnel for accurate operation

Larger footprint requires dedicated lab space

High-precision components need periodic calibration

Product Types

Standard Fabric Strength Meter – for general tensile and tear testing

High-Speed Model – optimized for production line efficiency

Pneumatic Clamp Version – for delicate or non-woven fabrics

Multi-Function Integrated Model – combines tensile, tear, seam slippage, and creep tests

FAQ

Q: Can it test both woven and non-woven fabrics?

A: Yes, it can handle a wide range of textile materials, including delicate non-woven fabrics.

Q: Does it comply with both Chinese and international standards?

A: Absolutely, it meets GB/T, FZ/T, ISO, ASTM, and JIS standards for tensile, tear, seam, and other tests.

Q: How is data managed and reported?

A: The instrument can connect to a PC via USB, display real-time data, generate reports, and store historical results for trend analysis.

Q: Can different clamps be used for special materials?

A: Yes, pneumatic, mechanical, and modular clamps are available to accommodate fabrics of varying thickness and texture.

Q: How often should it be calibrated?

A: Calibration is recommended annually, or whenever high-precision testing is required, to maintain compliance with standards.

As a professional laboratory testing instrument manufacturer, we specialize in high-quality Fabric Strength Meters and other textile testing solutions. For more information, custom solutions, or pricing, please contact us directly. Our expert team is ready to provide guidance for all your textile testing needs.