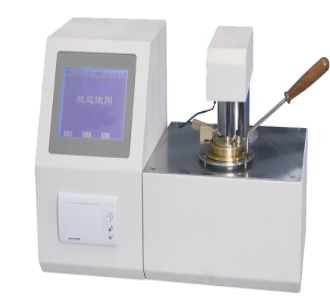

Cleveland Open Cup Flash Point Tester

Category:Other

Introduction

Product Introduction

The Cleveland Open Cup Flash Point Tester is an advanced automatic instrument designed to determine the flash point and ignition point of petroleum products whose ignition temperature exceeds 80°C (excluding crude oil and petroleum fuels). The system integrates modern control technology, enabling automated testing that closely matches the results of traditional manual instruments while significantly simplifying the operation.

The device is equipped with a PLC control system and a 5.5-inch color touch screen that allows comprehensive monitoring of test status and parameters on one interface. It supports full data processing and storage and provides reliable performance for laboratories requiring consistent and accurate flash point determination.

This instrument fully complies with ISO 2592 (Cleveland Open Cup Method) and other international standards.

Meeting Standards

ASTM D92 Standard Test Method for Flash and Fire Points by Cleveland Open Cup

ISO 2592 Petroleum Products — Determination of Flash and Fire Points — Cleveland Open Cup Method

IP 36 Determination of Flash and Fire Point — Cleveland Open Cup

AFNOR T60-118 Petroleum Products — Flash Point Test by Cleveland Open Cup

EN 22592 Petroleum Products — Flash and Fire Point Determination — Cleveland Method

DIN 51376 Testing of Mineral Oils — Flash and Fire Point Cleveland Apparatus

Product Advantages

The instrument is engineered to deliver high efficiency, strong repeatability, and reliable performance. Its main advantages include:

Automated flash point and ignition point testing, minimizing manual intervention and reducing human error.

Excellent test repeatability and reproducibility, ensuring accurate product characterization.

Full compliance with ISO 2592 and other major international Cleveland Open Cup standards.

User-friendly interface with a 5.5-inch color touch screen and PLC system that simplifies test setup and management.

Integrated data processing function for easy result tracking and report generation.

Built-in safety mechanisms suitable for working with flammable petroleum samples.

Efficient dual-fan cooling system ensures stable operation and reduces downtime between tests.

Product Features

Automatic testing process including sample heating, test flame application, flash detection, and ignition point determination.

Programmable Logic Controller (PLC) ensures precise control of parameters and test sequence.

Touch-screen display allowing real-time monitoring, data viewing, and parameter adjustment.

Micro printer included for convenient output of test reports.

Accurate temperature rise control with integrated heating system.

Automatic ignition system that applies the test flame at preset intervals.

Sensitive flash and ignition detection mechanism for reliable results.

Adequate ventilation design with a dual fan system directly cooling the test cup.

Technical Specifications

| Item | Specification |

|---|---|

| Dimensions | 550(W) × 400(D) × 320(H) mm |

| Table Size | 1000(W) × 600(D) × 800(H) mm |

| Power Supply | AC 220V, 50/60Hz, 15A |

| Weight | 30 kg |

| Instruction Manual | Available |

| Exhaust | ≥ 50 L/s |

| Tools Required | Propane gas, vacuum cleaner |

FAQ

1. What is the purpose of the Cleveland Open Cup Flash Point Tester?

It is used to determine the flash and fire points of petroleum products by heating the sample in an open cup while applying a test flame. This helps assess product safety, quality, and compliance with transportation and storage regulations.

2. How does this automatic tester differ from a manual Cleveland tester?

The automatic model controls heating rate, flame application, flash detection, and data recording automatically. This reduces operator fatigue, improves accuracy, and ensures test consistency across repeated runs.

3. What types of petroleum products can be tested?

The instrument is suitable for testing oils with flash points above 80°C, including lubricating oils, hydraulic oils, insulating oils, and other refined petroleum products. It is not intended for crude oils or petroleum fuels.

4. Do I need special ventilation when operating the device?

Yes. The instrument should be used in a well-ventilated laboratory with an exhaust capacity of at least 50 L/s, as small amounts of flammable vapors are released during testing.

5. How are test results stored or exported?

Results can be viewed on the touch screen, printed via the built-in micro printer, or stored digitally depending on the model configuration. Data management features help organize and track historical test results.