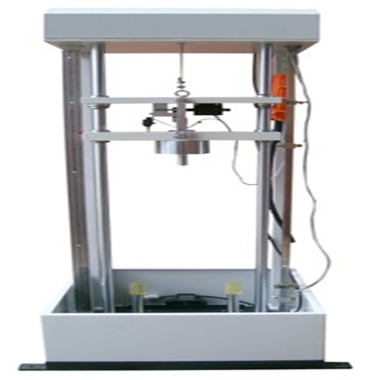

Car wire heat resistant water (salt water) testing machine

Category:Other

Introduction

Product Overview

The Car Wire Heat-Resistant Salt Water Testing Machine is designed for long-term testing (over 14 days) of automobile and locomotive wires under DC voltage and corrosive salt water conditions. It evaluates the heat resistance, insulation integrity, and corrosion resistance of wires in extreme conditions.

This tester is widely used in the automotive, railway, and wire manufacturing industries to ensure wires meet international durability and safety standards.

Applicable Standards

ISO 6722 – Road vehicles — 60/75°C and 90°C single-core cables

SAE J1128 – Low voltage automotive primary cables

QC/T 730 – Automotive wire and cable technical specifications

JASO D611 – Road vehicle wires

EN 50305 – Railway rolling stock wire tests

EN 50395 – Railway wire and cable environmental tests

Technical Parameters

| Parameter | Specification |

|---|---|

| Power supply | 380V, 50Hz |

| Heating power | 6000W (salt water resistance type) |

| Temperature range | Room temperature – 99.9℃ |

| Temperature control | Intelligent PID, accuracy ±0.2℃ |

| Thermocouple | PT100 anticorrosive type |

| Tank material | Anticorrosive pottery, ∅700 × 420 mm |

| Safety cover | PVC plate fence around pottery cylinder |

| Machine dimensions | 800 × 800 × 600 mm |

| Mixing method | Motor-driven, mixing rod made of non-metallic material |

| Water level control | Ball valve (anticorrosive), automatic water pump maintains water level |

| Optional | 48V DC power supply |

| Optional | High-voltage DC stability tester (JN-DC-50305): DC 0–5 kV, recordable |

Scope of Application

Automotive wires: Evaluates insulation and corrosion resistance under continuous DC voltage and salt water immersion.

Railway wires: Tests wires in locomotive applications for long-term durability.

Wire manufacturers and R&D labs: Provides accurate, standardized test data for quality control and certification purposes.

FAQ

1. What type of wires can be tested?

The machine supports automobile and locomotive wires, including single-core and multi-core cables, with PVC or heat-resistant insulation.

2. How long can the test run continuously?

The machine is designed for long-term testing over 14 days, simulating prolonged exposure to heat and salt water.

3. How is temperature controlled?

Temperature is monitored using a PT100 anticorrosive thermocouple and controlled by an intelligent PID system, maintaining accuracy within ±0.2℃.

4. How is the water level maintained?

An automatic water pump and ball valve system maintain a stable test water level, ensuring consistent testing conditions.

5. Can DC voltage be applied during testing?

Yes, the machine supports an optional 48V DC power supply. For high-voltage testing, the optional JN-DC-50305 tester allows DC voltage up to 5 kV to be applied and recorded.

6. Is the equipment safe from corrosion?

All components in contact with water are made of anticorrosive materials, including the pottery tank, PVC safety fence, and mixing rod.