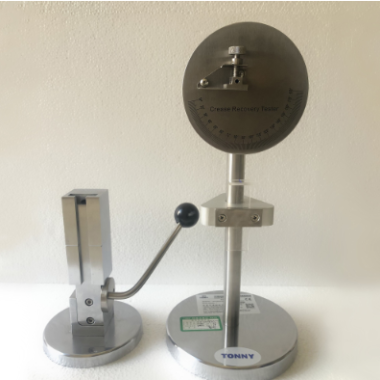

Environmental Stress Cracking Resistance Tester

Category:Other

Introduction

Product Introduction

The Environmental Stress Cracking Resistance (ESCR) Tester is a high-precision laboratory instrument designed to evaluate the susceptibility of thermoplastics, particularly polyethylene and other polymers, to environmental stress cracking. By simulating real-world chemical and mechanical conditions, this tester provides quantitative data on material durability, enabling manufacturers to optimize product formulations and ensure long-term performance under stress.

The instrument can perform both bending beam and constant load tests in a controlled temperature and chemical environment. It features an automated multi-specimen testing platform, integrated temperature control, and advanced data acquisition software to provide reliable, repeatable, and traceable results.

Applications

Testing the environmental stress cracking resistance of polyethylene, polypropylene, and other thermoplastics.

Assessing material performance in aggressive chemical environments, including oils, surfactants, and alcohols.

Applicable to automotive, packaging, consumer goods, and industrial plastics.

Used for research, quality control, and material certification.

Applicable Standards

ASTM D1693: Bending beam and constant load methods for polyethylene and thermoplastics.

ISO 22088-3: Notched specimen environmental stress cracking testing.

ISO 22088-2: Optional method for unnotched specimens.

GB/T 23275: Domestic standard for thermoplastic ESCR testing.

GB/T 1040.2 & GB/T 1040.3: Tensile performance reference for applied stress.

Industry & OEM Standards: VW, GM, Ford, and other automotive or industrial material testing standards.

Product Advantages

High Throughput

460-specimen capacity (46 vessels × 10 samples per vessel) allows simultaneous batch testing.

40% faster cycle compared to conventional models.

Precision Engineering

Uniform stress application for consistent and repeatable results.

PID-controlled temperature with ±0.2°C stability.

Compatible with a wide range of solvents and temperatures (-10°C to 100°C).

User-Centric Workflow

ASTM-compliant sample prep tools and prefabricated jigs included.

Intuitive touchscreen interface with pre-loaded test protocols.

Safety and Compliance

Chemical-resistant construction using 316L stainless steel and PTFE-coated components.

Audit-ready data logging compliant with 21 CFR Part 11.

Adaptive Testing

Solvent versatility supports surfactants, hydrocarbons, and polar solvents.

Modular bath system allows flexible vessel arrangement and rapid bath equilibration.

Technical Parameters

| Specification | Details |

|---|---|

| Temperature Range | -10°C to 100°C |

| Temperature Accuracy | ±0.2°C (±0.1°C with calibration kit) |

| Sample Capacity | 460 specimens (46 vessels × 10 samples) |

| Stress Load Range | 0–50N (0.1N resolution) |

| Power Supply | 220V/50Hz (110V/60Hz optional) |

| Bath Volume | 60L (expandable to 120L) |

| Dimensions (W×D×H) | 1.200 × 800 × 1.850 mm |

| Weight | 280 kg (net) |

| Data Acquisition | 100Hz sampling, crack event capture |

| Safety | Leak-proof magnetic drive, fume extraction compatible |

Accessories & Options

Sample Preparation Kit: Milling cutters, polishing films, and bending beam jigs.

Solvent Management: Explosion-proof storage cabinet and recirculating chillers.

Advanced Analytics: AI-assisted crack length measurement software and remote monitoring.

Calibration Bundle: NIST-traceable temperature and force calibration kits.

Extended Warranty: Up to 5 years for bath and control components.

FAQ

Q1: What types of plastics can be tested?

A: Primarily polyethylene, polypropylene, and other thermoplastics that are prone to environmental stress cracking.

Q2: Can this machine test notched and unnotched specimens?

A: Yes, it is compatible with both ASTM D1693 notched bending beams and ISO 22088-2/3 unnotched or notched specimens.

Q3: What chemical solvents are supported?

A: Surfactants, oils, alcohols, and other polar/non-polar solvents commonly used in ESCR testing.

Q4: How is temperature controlled and monitored?

A: The system uses PID-controlled baths with ±0.2°C stability and integrated level sensors for automatic detection and prevention of test interruptions.

Q5: How is data recorded and exported?

A: Data is sampled at 100Hz, securely logged, and can be exported wirelessly to LIMS or analyzed with advanced crack measurement software.