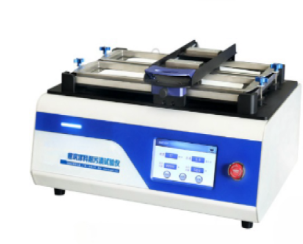

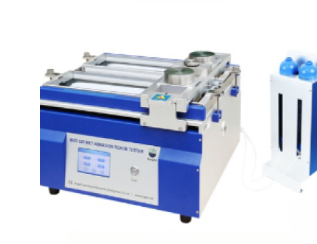

Multifunctional scrubbing machine

Category:Other

Introduction

Product Introduction & Applications

The Multifunctional Scrubbing Machine is designed to evaluate the scrubbing resistance of various materials by simulating real-life cleaning conditions. By changing friction heads, it can perform wet scrubbing, sponge scrubbing, stain resistance, solvent wiping (e.g., alcohol, MEK), cleaning cloth scrubbing, and rubber dry rubbing tests. Its dual-channel design allows simultaneous testing with two different media, providing highly accurate and repeatable results. This instrument is widely used in coatings, textiles, paper, packaging, and other material industries for quality control and product development.

Standards

GB/T 1767 — Paints and varnishes: Scrub resistance

ISO 11998 — Paints and varnishes: Determination of scrub resistance of coatings

ASTM D2486 — Standard Test Method for Scrub Resistance of Wall Paints

DIN 53778 — Coatings: Resistance to wet abrasion

JIS K 5400 — Paints and varnishes: Resistance to scrub

Technical Parameters

| Parameter | Details |

|---|---|

| Running Speed | 5–95 times/min, continuously adjustable |

| Friction Stroke | 0–300 mm, continuously adjustable |

| Run Times | 0–99,999 times, adjustable |

| Washing Medium Container Capacity | 500 ml × 2 |

| Voltage | AC 110V/220V, 50/60 Hz |

| Overall Dimensions | 500 × 460 × 280 mm |

| Net Weight | 55 kg |

Usage Notes

Ensure samples are securely clamped before starting the test to prevent slippage.

Select the appropriate friction head according to the test standard.

Adjust the friction speed, stroke, and washing medium flow rate according to material type.

Clean and dry the machine components and washing medium containers after each test.

Operate the instrument in a dry, stable environment to maintain measurement accuracy.

FAQ

What types of tests can this machine perform?

It can perform wet scrubbing, sponge scrubbing, stain resistance, solvent wiping, cleaning cloth scrubbing, and rubber dry rubbing tests.

Can two different media be used simultaneously?

Yes, the dual-channel design allows testing with two different washing media at the same time.

How adjustable are the test parameters?

Running speed, stroke, run times, and washing medium flow rate are all continuously adjustable.

Is this machine suitable for different materials?

Yes, it is widely used for coatings, textiles, paper, and packaging materials.

How do I maintain the instrument for long-term use?

Regularly clean and dry the friction heads, washing medium containers, and other main components; ensure the machine is operated in a stable environment.