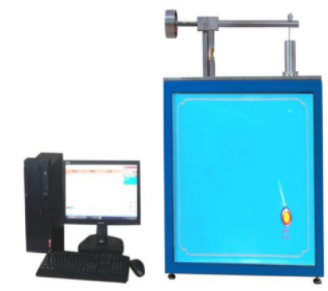

Automotive wire flexibility testing machine

Category:Other

Introduction

The Automotive Wire Flexibility Testing Machine is designed to assess the flexibility and mechanical durability of automotive wires under repeated bending. This test ensures that wires maintain their mechanical and electrical integrity after repeated stress, which is critical for automotive safety and reliability.

It is widely used by automotive manufacturers, wire producers, and testing laboratories to verify that wires comply with industry standards for flexibility.

Applicable Standards

Ford Global Wire Specification – PART NO. ES-AU5T-1A348-AA

Technical Parameters

| Parameter | Specification |

|---|---|

| Drawing speed | 50 mm/min (adjustable) |

| Load applied | 2 N |

| Guide wheel | Outer diameter: 36 mm, Inner diameter: 29 mm, Inner groove radius: 9 mm, Thickness: 10 mm |

| Distance between guide wheel centers | 42 mm |

| Stretch length | 125 mm, automatic stop at set length |

| Tensile meter | Maximum range: 50 kg, digital display |

Scope of Application

Evaluates the mechanical bending performance of automotive wires.

Ensures wires can withstand repeated bending without cracking or conductor breakage.

Suitable for wire quality inspection, R&D testing, and validation for automotive wiring harness applications.

FAQ

1. What type of wires can be tested?

The machine is suitable for automotive wires with nominal cross-section ≤3.0 mm², including single-core and multi-core wires with PVC or heat-resistant insulation.

2. How is the bending cycle controlled?

The machine uses preset stretch length (125 mm) with an automatic stop function to ensure consistent and repeatable bending cycles.

3. Can the drawing speed be adjusted?

Yes, the drawing speed is adjustable, with a default speed of 50 mm/min, allowing adaptation to different wire types and testing requirements.

4. How is the applied load measured?

The machine applies a constant 2 N load, and the tensile meter provides a digital readout up to 50 kg, ensuring precise control and monitoring.

5. What is the role of the guide wheels?

The guide wheels with precise groove radius and spacing ensure that wires are bent consistently and prevent slipping or uneven stress during testing.