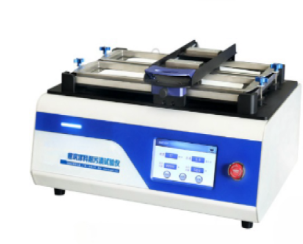

Large diameter blasting test machine

Category:Other

Introduction

Product Introduction

The Large Diameter Blasting Test Machine is designed for high-pressure burst and long-term hydrostatic pressure testing of large-diameter pipes and fittings. Using linear pressurization technology, it accurately determines the mechanical performance of pipes under short-term high-pressure and long-term sustained load conditions, ensuring the safety and reliability of pipeline products in extreme working environments.

Application Scope

Suitable for HDPE, PVC, composite materials, steel-plastic pipes, and other industrial pipelines. Widely used in petroleum, natural gas, water engineering, fire protection, and industrial pipeline manufacturing and quality control.

Applicable Standards

ASTM D1599: Short-term hydrostatic burst testing of thermoplastic pipes

ISO 1167: Long-term hydrostatic pressure testing of pipes

Enterprise-specific and industry standards (optional)

Product Advantages

High Precision: Linear pressurization algorithm maintains ±0.5% FS pressure accuracy and captures transient rupture data in real time.

High Efficiency: Modular pump system with 250 L/min flow rate (upgradeable to 1,200 L/min) shortens test cycles.

Safety & Reliability: Explosion-proof enclosure, dual pressure relief protection, audible and visual alarms, and emergency stop function.

Intelligent Operation: 15-inch touchscreen HMI with preloaded standard test sequences and customizable pressure ramp profiles.

Wide Compatibility: Supports pipes up to Ø1,600 mm and compatible with metric/imperial thread connections.

Technical Parameters

| Parameter | Specification |

|---|---|

| Pressure Range | 0–600 Bar (8,700 psi) |

| Flow Rate | 250 L/min @ 100 Bar (upgradeable to 1,200 L/min) |

| Pump Type | Modular VFD-driven triplex plunger pump |

| Pressure Ramp Rate | 0.1–10 Bar/sec adjustable |

| Temperature Range | 5–60°C (ambient) |

| Power Supply | 400V/50Hz 3-phase (CE certified) |

| Test Chamber Dimensions | 2,200 × 1,200 × 1,500 mm |

| Net Weight | 1,200 kg |

Accessories & Optional Modules

Pressure Calibration Kit (NIST-traceable, 0.05% FS accuracy)

High-Flow Pump Head Upgrade

Thermal Expansion Module (water bath 60–95°C)

Pre-scored Rupture Disk Kit

Data Acquisition & Analysis Software (BurstVision Pro™, CloudLink remote monitoring)

Safety Bundle (ATEX-certified enclosure + CO₂ fire suppression system)