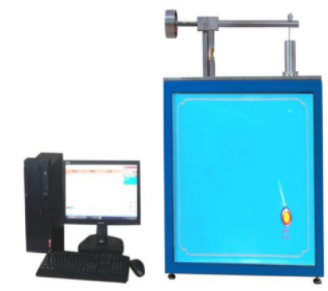

Wire Bending Test Machine

Category:Other

Introduction

Product Overview

The Wire Bending Test Machine is designed to evaluate the mechanical durability and flexibility of wires under repeated bending stress. The wire is fixed in the adjustable fixture, inserted through a hole corresponding to its thickness, and subjected to 200 rotations (or a preset number) to simulate real-world bending conditions.

This tester is widely used in automotive, aerospace, electronics, and industrial wiring quality control to assess insulation integrity, conductor strand breakage, and overall wire durability. It supports both positive and negative bending operations and can automatically stop when the preset number of cycles is reached.

Applicable Standards

JIS C 3005 – Tests for electric wires: bending characteristics

UL 87 – Standard for electrical wire performance

Technical Parameters

| Parameter | Specification |

|---|---|

| Fixture action | Manual |

| Fixture spacing | 0–500 mm, adjustable |

| Total number of cycles | 0–999,999, can be manually set |

| Test rate | 20 cycles/min |

| Off-center distance | 50, 75, 100, 150 mm |

| Sample diameter (parallel section) | φ4, φ6, φ8, φ10, φ12, φ15, φ18, φ20 mm |

Scope of Application

Automotive wires: Evaluates insulation and conductor durability under repeated bending.

Industrial wiring: Assesses flexibility and mechanical strength for control and power cables.

Aerospace and electronics: Ensures compliance with stringent bending and fatigue requirements.

R&D and QC laboratories: Provides reliable data for product development and quality control.

FAQ

1. What types of wires can be tested?

The tester supports round wires with diameters ranging from φ4 mm to φ20 mm, including copper, aluminum, and insulated wires used in automotive, aerospace, and industrial applications.

2. How is the bending process conducted?

The wire is inserted through the appropriate round hole, fixed in the adjustable fixture, and subjected to rotational bending. Both positive and negative rotation is supported. The tester records and evaluates any cracking, conductor breakage, or insulation damage.

3. Can the number of bending cycles be customized?

Yes, the total number of bending cycles can be set from 0 to 999,999. The machine can also automatically stop once the preset number is reached, ensuring consistent testing.

4. How is wire damage evaluated?

After testing, the wire is visually inspected for cracks, conductor strand breakage, and insulation damage. Some laboratories may combine this with electrical or mechanical testing to assess performance after bending.

5. What industries commonly use this machine?

The machine is used in automotive wire manufacturing, aerospace cable production, industrial and electronic wiring, and laboratory quality testing to ensure wires meet flexibility and fatigue resistance standards.